Researchers at Penn Engineering have developed a new approach to improve the durability of 3D-printed metamaterials by introducing controlled irregularities into their structure. The team found that by offsetting the connection points in lattice structures by approximately 15% from their regular positions, they could create materials that are 2.6 times more resistant to cracking compared to traditional ordered designs.

“The samples that performed the best, in which it was most difficult for a crack to grow, did not consist of regular repeating patterns,” explained Sage Fulco, the paper’s lead author. This design approach mirrors natural materials like bone and nacre (mother-of-pearl), which use microscale irregularities to achieve higher resilience.

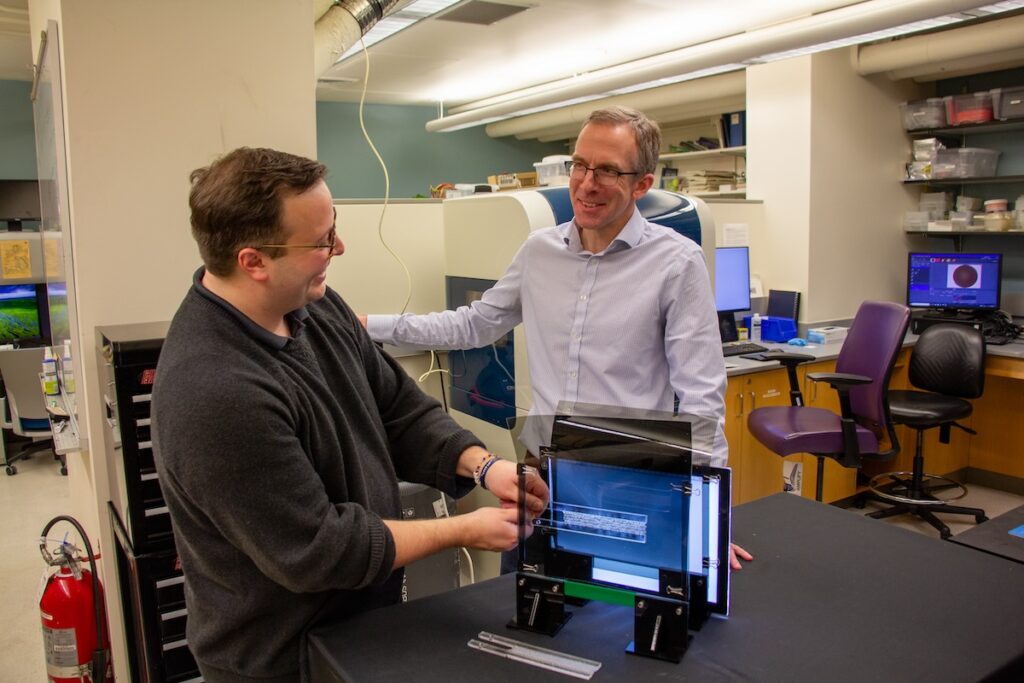

The research team tested their concept using laser-cut polymethylmethacrylate (PMMA) specimens and conducted thousands of computational simulations. Their findings showed that while the disordered structures exhibited slightly reduced strength (≤25%), they maintained similar stiffness levels to traditional ordered lattices while significantly improving crack resistance.

Using photoelastic imaging, the researchers observed that cracks in disordered lattices spread across a wider area instead of following straight paths typical in ordered structures. This distributed damage pattern helps explain the enhanced toughness of the irregular designs.

The new approach offers practical advantages over traditional toughening methods, as it relies solely on geometric modifications rather than material additions or specialized coatings. According to Kevin Turner, Professor at Penn Engineering, while disordered systems present more complex design challenges, they can be implemented using existing manufacturing methods like 3D printing and laser cutting.

The technique shows potential for applications across various industries, including aerospace, medical devices, and automotive sectors. Implementation primarily requires modifications to design files rather than changes to production processes, making it potentially accessible to manufacturers using current equipment.

Source: blog.seas.upenn.edu