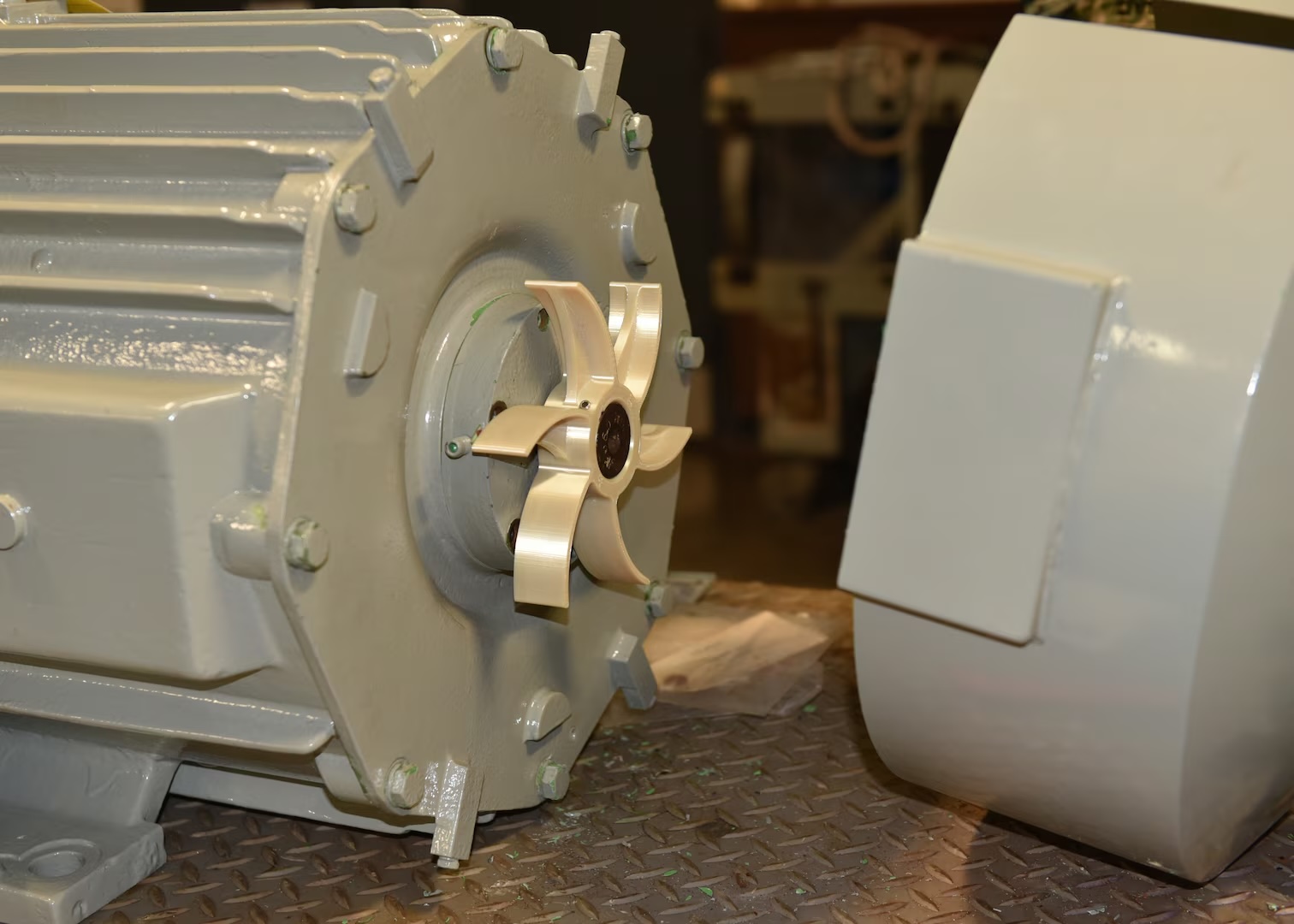

The Southeast Regional Maintenance Center (SERMC) has successfully used 3D printing to manufacture a replacement cooling rotor for an Arleigh Burke-class guided missile destroyer’s chilled water pump. The six-blade component is not sold separately through the Navy supply system, typically requiring the purchase of an entire new pump unit.

The SERMC team developed four prototypes over two weeks using reverse engineering techniques. They began with a low-cost polymer version of the original aluminum part before coordinating with Fleet Readiness Center Southeast Detachment Mayport to select the final material. The finished component was manufactured using an aerospace-grade thermoplastic known for strength, heat resistance, and flame retardancy.

The cost difference between 3D printing and conventional replacement proved significant. A prototype blade cost $17.63 to produce, while the final blade cost $131.21. Replacing the entire motor through traditional procurement would have cost $316,544.16.

“Sailors at SERMC are always looking for new applications for 3D printing to expand our capabilities and save time, resources, and money,” said Capt. Kiah Rahming, SERMC’s commanding officer. “This effort is a testament to the ingenuity and drive of our team.” The printed component has been operationally tested, certified, and installed aboard a destroyer. These cooling pump rotors are used across all ship types in the Navy fleet.

Source: navsea.navy.mil