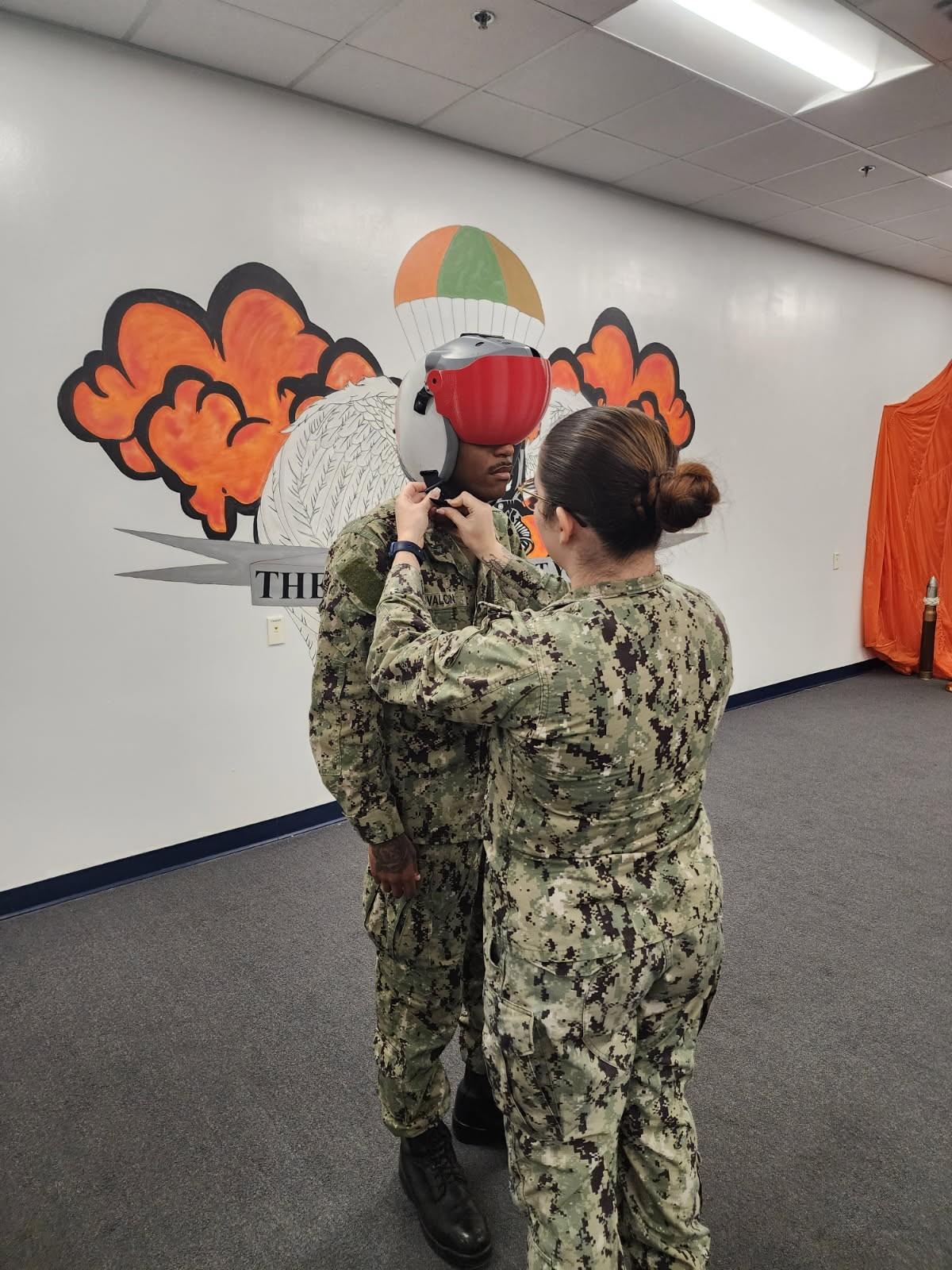

The U.S. Navy has developed a 3D printed version of the Joint Helmet Mounted Cueing System (JHMCS) visor through a collaborative effort between multiple naval commands. The project involved the Naval Aviation Training Systems and Ranges Program Office (PMA-205), Naval Education and Training Command (NETC), Center for Naval Aviation Technical Training (CNATT), and Commander, Naval Air Forces training and readiness (CNAF N7).

The original JHMCS visor cost $870 per unit and required multi-year procurement timelines, creating delays in training curriculum and fleet sustainment. With CNATT requiring approximately 40 visors annually, the existing supply model presented fiscal and operational challenges for the Navy’s training programs.

The team developed a prototype visor using Acrylonitrile Butadiene Styrene, a 3D printing filament, that meets essential design requirements including dimensional accuracy and smooth integration with Helmet Display Units. The new manufacturing approach reduces costs by 65 percent and shortens delivery timelines from years to weeks.

“This effort is a prime example of how collaboration and innovation across commands can deliver real results for the fleet,” said Capt. Jonathan Schiffelbein, PMA-205 program manager. “By leveraging additive manufacturing, our teams not only met critical training requirements but also advanced readiness and cut lifecycle costs, directly supporting our Sailors and the mission.”

The Navy has created a technical data package to ensure the visors can be replicated across fleet intermediate level maintenance print sites. This approach provides a scalable supply solution that can be implemented at multiple locations within the Navy’s maintenance network.

Source: navair.navy.mil