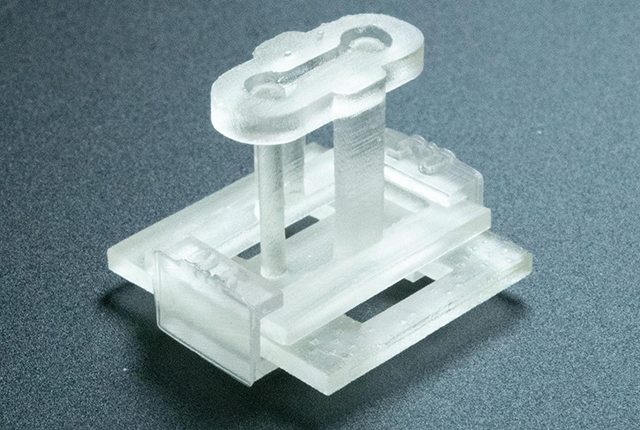

Researchers at UW Medicine and the University of Washington have developed a new 3D-printed device that enhances tissue modeling capabilities. Named STOMP (Suspended Tissue Open Microfluidic Patterning), the fingertip-sized device allows scientists to create more complex tissue models with precise control over cell arrangement. The technology builds upon existing methods where cells are suspended in gel between posts, but offers improved ability to study multiple tissue types together.

The device works through capillary action to distribute different cell types in customized patterns within a suspended tissue. This approach enables researchers to recreate biological interfaces such as bone-ligament connections or combinations of fibrotic and healthy heart tissue. STOMP includes degradable walls, a feature that allows the device to be removed while leaving the engineered tissues intact.

Professors Nate Sniadecki and Ashleigh Theberge led the interdisciplinary team that developed the platform. “This method opens new possibilities for tissue engineering and cell signaling research,” said Theberge. “It was a true team effort of multiple groups working across disciplines.”

The researchers demonstrated STOMP’s capabilities through two experiments: one comparing contractile dynamics between diseased and healthy heart tissue, and another modeling the ligament connecting a tooth to its bone socket. The technology provides a solution to common challenges in tissue engineering, including the tendency of cells to pull away from mold walls.

The project received support from multiple National Institutes of Health grants and various research foundations. The research findings were published in the journal Advanced Science, with first authors Amanda Haack and Lauren Brown contributing to the paper alongside faculty members from chemical engineering, bioengineering, and oral biology departments.

Source: newsroom.uw.edu