Researchers from Monash University (Australia) and the Arts et Métiers Institute of Technology (France), have published a paper on tissue engineering in the Advanced Functional Materials journal. This study highlights a new approach that combines top-down co-extrusion and bottom-up 3D printing to create biomaterials with intricate layered architecture.

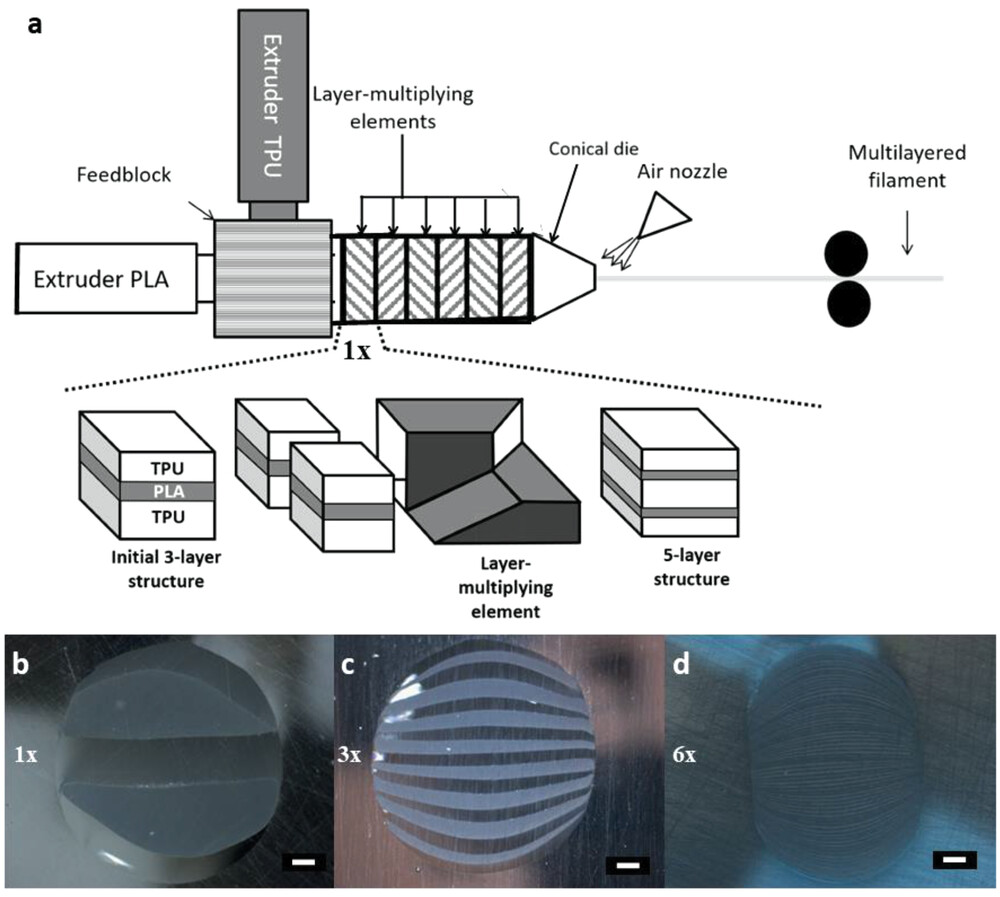

Traditionally, mimicking complex biological structures while fostering cell growth has proven challenging. However, the study presents a two-step method: utilizing multilayer co-extrusion to produce alternating layers of biodegradable poly(lactic acid) (PLA) and elastic thermoplastic polyurethane (TPU), and then using 3D printing to build sophisticated tissue engineering scaffolds.

Importantly, this approach maintains the layered structure during printing, resulting in continuous interfaces between polymer phases. By adjusting the co-extrusion process, researchers have achieved filaments with varying layer thicknesses, enabling the creation of 3D constructs with nanoscale polymer layers. Mechanical assessments demonstrated improved properties in certain architectures, blending the strengths of both PLA and TPU.

The study’s impact extends to cardiac tissue engineering, where the multilayered scaffolds influenced the alignment, morphology, and functionality of rat heart muscle cells (cardiomyocytes). The research holds significant promise for heart health, as optimal cardiomyocyte growth and function are vital.

Beyond its cardiovascular applications, the study’s innovative fusion of fabrication techniques offers a versatile approach applicable to diverse tissue engineering endeavors, from bone regeneration to wound healing.

You can read the full paper, titled “Fabrication of Architectured Biomaterials by Multilayer Co-Extrusion and Additive Manufacturing” at this link.

Source: onlinelibrary.wiley.com

Come and let us know your thoughts on our Facebook, Twitter, and LinkedIn pages, and don’t forget to sign up for our weekly additive manufacturing newsletter to get all the latest stories delivered right to your inbox.