Epitum, a UAE-based developer of 3D printing technologies, bridges the gap between industrial-grade performance and affordability in 3D printing. Focused on integrating additive manufacturing into production lines, this innovative player aimed to create solutions that are not only cutting-edge but also accessible for businesses of all sizes. The result? A professional FFF 3D printer by Epitum designed to address the challenges of modern manufacturing while maintaining affordability.

Challenges in Adopting 3D Printing for Production

Despite its potential, 3D printing has faced significant hurdles in industrial adoption. One central pain point is the complexity of removing supports, which increases post-processing time and material waste. Multi-material printing adds another layer of difficulty, as traditional systems require wipe towers to switch between materials, slowing down the process and complicating workflows. Additionally, intricate geometries—such as closed systems or hollow structures—are often impossible to produce with conventional methods like casting or molding.

The gap between desktop and industrial-grade 3D printers further complicates matters. Desktop models lack the precision and reliability needed for professional use, while industrial machines remain prohibitively expensive for many businesses. It leaves small and medium enterprises struggling to adopt additive technologies effectively. Dissolvable supports have emerged as a key solution, streamlining production and enabling automation.

Breakthrough Technologies

Listening to its customers, Epitum developed two groundbreaking technologies that tackle these challenges head-on—all at an impressively competitive price point.

JetSmart®:

Their dual-nozzle system revolutionizes multi-material printing. Unlike traditional setups, both nozzles are housed on a single extruder, allowing seamless material switching without the need for wipe towers. This innovation drastically reduces downtime, minimizes plastic waste, and enhances overall efficiency.

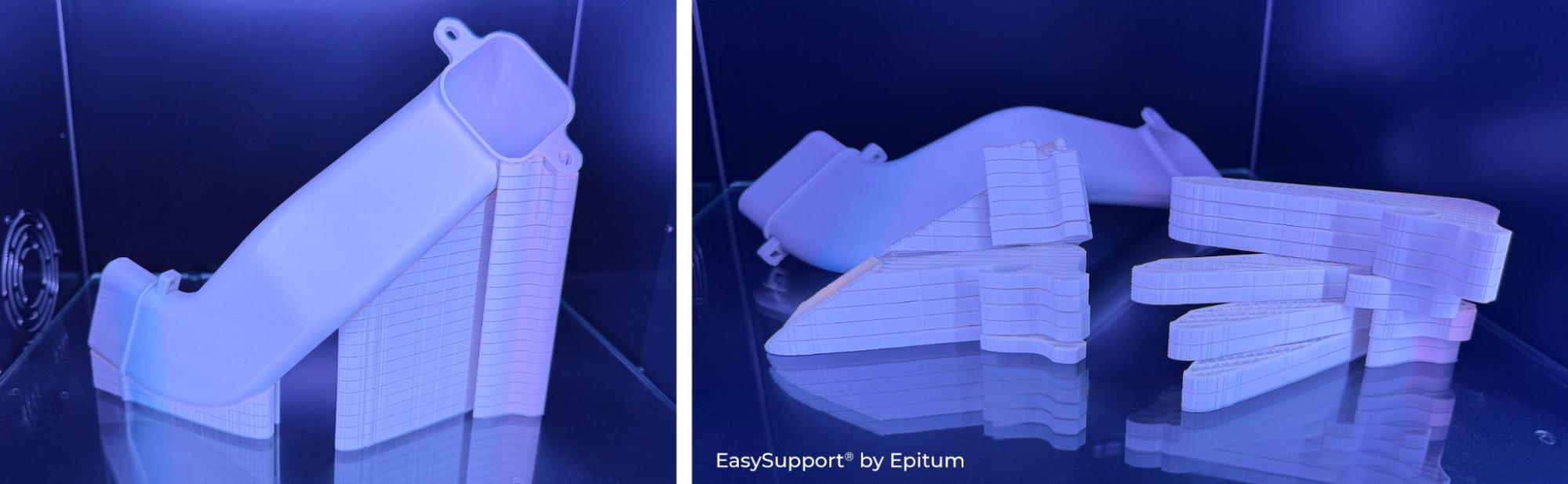

EasySupport®:

This unique support generation algorithm redefines how supports are built. Thanks to optimized interface and sub-interface layers, EasySupport® ensures effortless support removal—supports literally crumble away by hand. Its standout feature is the infill pattern, a structure that allows solvents to penetrate every layer of the support. This makes it ideal for fully dissolvable materials like PVA or chemically soluble polymers, ensuring smooth post-processing even for complex designs. For example, printing a pipe with EasySupport® reduced the total cost of the final product from $34 to $11 while maintaining structural integrity. For a batch of only 100 units, this translates to savings of $2,400!

Advantages for Your Business

These innovations offer tangible benefits for B2B clients. By reducing post-processing costs and minimizing material waste, their technologies empower businesses to focus on what truly matters: production. Complex geometries, once deemed impossible with traditional methods, are now achievable, opening doors to new possibilities in the automotive, medical, educational, and industrial sectors.

While many 3D printer manufacturers compromise precision for speed or sustainability for affordability, Epitum’s technology achieves all four without trade-offs. This synergy of speed, accuracy, eco-friendliness, and cost efficiency makes it a versatile solution for industries like industrial production, small-batch production, automotive, and healthcare. Whether prototyping, producing functional parts, or scaling up manufacturing, Epitum’s 3D printer delivers unmatched value while maintaining budget flexibility.

A Step Forward in Additive Manufacturing

At Epitum, they believe their technologies represent a leap forward in additive manufacturing—especially for businesses seeking efficient, scalable solutions.

“We are likely the only company on the market that can effectively print with two nozzles. Having mastered this capability, we shifted focus to streamlining support structures. We developed a method to significantly reduce the cost of 3D printing with soluble supports while retaining its benefits—thanks to our pre-existing optimized support mode. This flexible solution became feasible due to our ongoing development of proprietary software. It allows us to implement innovations faster and better support businesses.” — Andrey Isupov, CEO and Lead Developer at Epitum.