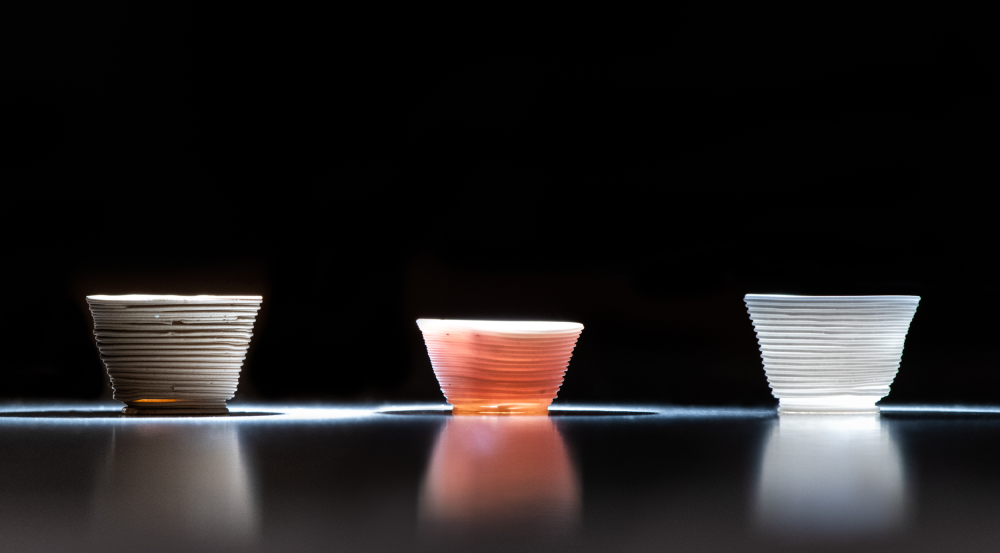

Researchers at MIT Lincoln Laboratory have developed a new low-temperature process for 3D printing glass objects. This method creates complex glass structures without requiring the high-temperature processing typically associated with glass manufacturing. The technique uses direct ink writing to build objects layer by layer at room temperature, followed by curing at just 250°C—significantly lower than the 1,000°C+ temperatures traditionally needed for glass processing.

The process employs custom inks made from inorganic materials combined with a silicate solution. These components allow engineers to tailor the optical, chemical, and electrical properties of the resulting glass composite. After printing, the structures are cured in a mineral oil bath and then rinsed with an organic solvent to remove residual material.

Testing has demonstrated that the printed glass items maintain high resolution, good thermal stability, and experience minimal shrinkage during production. The method overcomes key limitations of conventional 3D printing materials like plastics and metals, which can suffer from mechanical, chemical, and thermal instabilities. Using inorganic composite glasses addresses many of these issues.

The technique could enable more widespread adoption of glass in additive manufacturing applications. Potential uses include microfluidic systems, free-form optical lenses or fiber, and high-temperature electronic components. The approach is particularly valuable for components that would be difficult or impossible to produce using traditional glass manufacturing methods.

Current research efforts are focused on improving the optical clarity of the printed glass. Scientists are also developing new ink formulations to expand the range of chemical and electrical properties available in the printed objects. The accessible nature of the ink ingredients and the geometric freedom offered by direct ink writing provide significant versatility for creating specialized glass structures.

Source: ll.mit.edu