Spanish researchers have developed polymer blends that enhance interlayer bonding for FFF/FDM 3D prints. By mixing together TPU and ABS in various proportions, they have reportedly created new materials with “the appearance of new supramolecular interactions via hydrogen bonding“. In effect, the blends have far better interlayer bonding while displaying no loss in yield strength. The blend material could serve as a good thermoplastic alternative for conventional polymers, providing better strength operating under lower heating requirements for the bed and nozzle.

While FFF/FDM have come a long way, there are still quite some drawbacks. Compared to a method like injection molding, mechanical properties can be 50% lower for printed parts. Pure ABS, for example, decreases in tensile yield strength from 49.94 to 27.59 MPa after printing. Complex prints can suffer due to a lack of homogeneous distribution of the material and the presence of air gaps between the layers. This makes the printed objects more brittle and causes them to suffer from high anisotropy.

The researchers posited that Thermoplastic Elastomer (TPEs) blends were a good solution to this issue. They state that such material composites have good adhesive properties and some can also be processed without a heated bed. Therefore, their research settled on the idea of mixing ABS, one of the most common printed thermoplastics, with TPU. They also note that adhesive properties were better in the blend, while still maintaining the desirable mechanical properties.

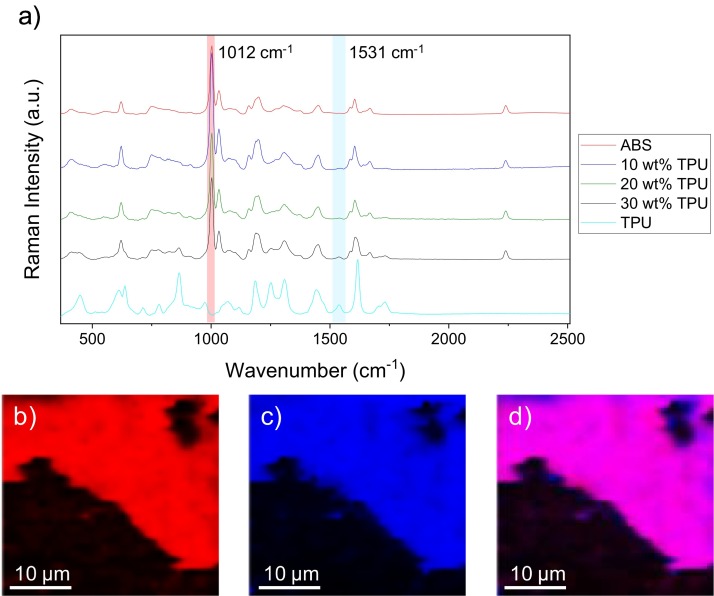

“It can be observed that TPU characteristic peaks increase proportionally with the TPU content in the blends,” stated the researchers. “This is a first indication of good compatibility between ABS and TPU in the blends, since we cannot identify separated regions of ABS and TPU, at least within the spatial resolution of the Raman laser. To investigate more in detail the chemical composition of the ABS:TPU blends, XY Raman mappings of the blends were performed.”

Enhanced ABS/TPU Polymer Blend

The researchers went through various proportions of blends to arrive at ideal ones. They prepared the 3D printer filament using a single-screw extruder (Noztek, UK) at a temperature of 230 °C with a screw speed of 60 rpm. They extruded about 50 g worth of filaments with 1.75 ± 0.10 mm diameter using ABS as the matrix and TPU as the additive. The polymer blends were composed of 10 wt%, 20 wt% and 30 wt% TPU and 90 wt%, 80 wt% and 70 wt% ABS respectively.

They found that 10-20% TPU was a good for enhanced interlayer bonding without decreases the yield strength. Similarly, the 30% TPU version also allowed for printing with no additional bed heating. This gives makes it both strong and convenient for less elaborate printing setups. The researchers go even further stating:

“Due to their commercial availability and simple preparation of the blends, we believe these materials are particular interesting for large-scale, industrial applications as an alternative to pure ABS.”

Featured image courtesy of the researchers and Universidad de Cádiz. The full study is available here.