In a major advancement for metal additive manufacturing, researchers at Lawrence Livermore National Laboratory (LLNL) and their academic partners have developed a new method that significantly enhances the optical absorptivity of metal powders used in 3D printing. This breakthrough could lead to more efficient and higher-quality production of metal parts, especially for challenging materials like copper and tungsten.

Addressing Challenges in Metal Additive Manufacturing

Metal 3D printing, particularly laser powder-bed fusion (LPBF), has transformed the manufacturing landscape by enabling the production of complex and customized components that traditional methods often struggle to achieve. However, one ongoing issue is the high reflectivity of certain metals, such as copper, which can hinder energy absorption during the printing process. This inefficiency not only affects print quality but also increases energy consumption, leading to higher operational costs and potential machine damage.

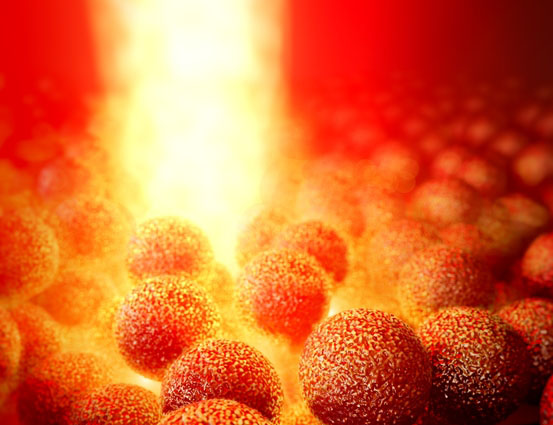

To tackle this issue, a team of scientists from LLNL, Stanford University, and the University of Pennsylvania introduced an innovative approach called wet chemical etching. This technique modifies the surface of metal powders by creating nanoscale textures, allowing them to absorb more energy during the laser-melting process. The study, published in Science Advances, reports that this method has increased the absorptivity of metal powders by up to 70%.

The Wet-Etching Process and Its Impact

The process involves immersing metal powders, such as copper and tungsten, in a specially formulated solution that selectively removes material from the surface. This results in the formation of nanoscale grooves and textures, enhancing the powder’s ability to absorb laser light. The team used advanced imaging techniques like synchrotron x-ray nanotomography to visualize the surface features of the powders and accurately model how these modifications influence energy transfer during 3D printing.

The enhanced absorptivity allows for more efficient energy usage during printing, which is especially beneficial for materials like copper that are traditionally difficult to work with. “Our method enhances the absorptivity of copper without compromising its desirable properties, such as high thermal and electrical conductivity,” said Philip DePond, co-lead author and LLNL materials scientist. “We demonstrated that laser-powder interactions extend beyond the melt pool, which can be advantageous for the printing process.”

Efficiency Gains and Sustainable Manufacturing

The improved absorptivity of metal powders is a significant step toward reducing energy consumption in manufacturing. The researchers found that by using less energy, they could print high-purity copper and tungsten components with relative densities of up to 99%. This not only improves the quality of printed parts but also minimizes the environmental impact of the manufacturing process by reducing the energy required for production.

For example, the team was able to print copper structures using less than 100 J/mm³ of energy, a range typically used for materials like titanium and stainless steel. Tungsten, which usually requires high energy input, was printed using about 700 J/mm³, one-third less energy than traditional methods.

“This breakthrough opens up new possibilities for industries to print copper without needing expensive, custom-built machines,” explained DePond. “It lowers the barrier of entry for producers, making metal additive manufacturing more accessible and cost-effective.”

Broad Implications for Industry

The ability to print with reduced energy and higher precision could have an immediate impact on various industries. According to Dan Flowers, leader of LLNL’s Energy Security Program, this method could benefit applications ranging from heat exchangers to clean energy technologies. “Efficient printing of copper can support the development of decarbonization technologies and advance our low-carbon energy mission,” Flowers noted.

Looking ahead, the researchers are interested in exploring how this technique could improve the mixing of powders with different energy requirements for melting. They also plan to continue optimizing the process to enable the production of even more complex and durable metal parts.

The new wet-etching technique marks a major step forward in the development of sustainable and efficient metal 3D printing technologies, potentially transforming the way industries produce high-performance components with challenging materials.

For further reading you can find the full paper titled: “High absorptivity nanotextured powders for additive manufacturing” at science.org.