Nanyang Technological University (Singapore) and California Institute of Technology (US) have recently published a paper in Nature, detailing research into a new chain mail-like “smart fabric” that changes stiffness when compressed.

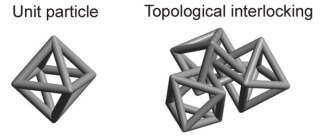

The chain mail itself is printed with Nylon, and each chain link is in the shape of an octahedron, as you can see below. The hollowness of the unit particles allows low density and yet high tensile stiffness from the overall fabric.

The individual “unit particles” are topologically interlocked, meaning that they are linked like chain mail, constraining the unit particles to form the shape of a continuous loose fabric. The paper does indeed state that the fabric is more like a 2 dimensional structure overall, despite the obviously 3 dimensional unit particles. The chain mail specimens were printed in single pieces, ready to function.

To control the stiffness, the researchers placed the chain mail into a transparent plastic back, and removed the air from the bag using vacuum. This effectively compressed the unit particles together, causing the unit particles to jam together, restricting the movement of each particle, and therefore increasing the stiffness of the overall fabric structure. In fact the mechanism by which these particles lock together is called “jamming transition”, because they jam together, see?

The pressure increases the packing density of the fabric, causing each particle to have more contact with its neighbours, resulting, for the octahedron-based fabric, in a structure that is 25 times more rigid.

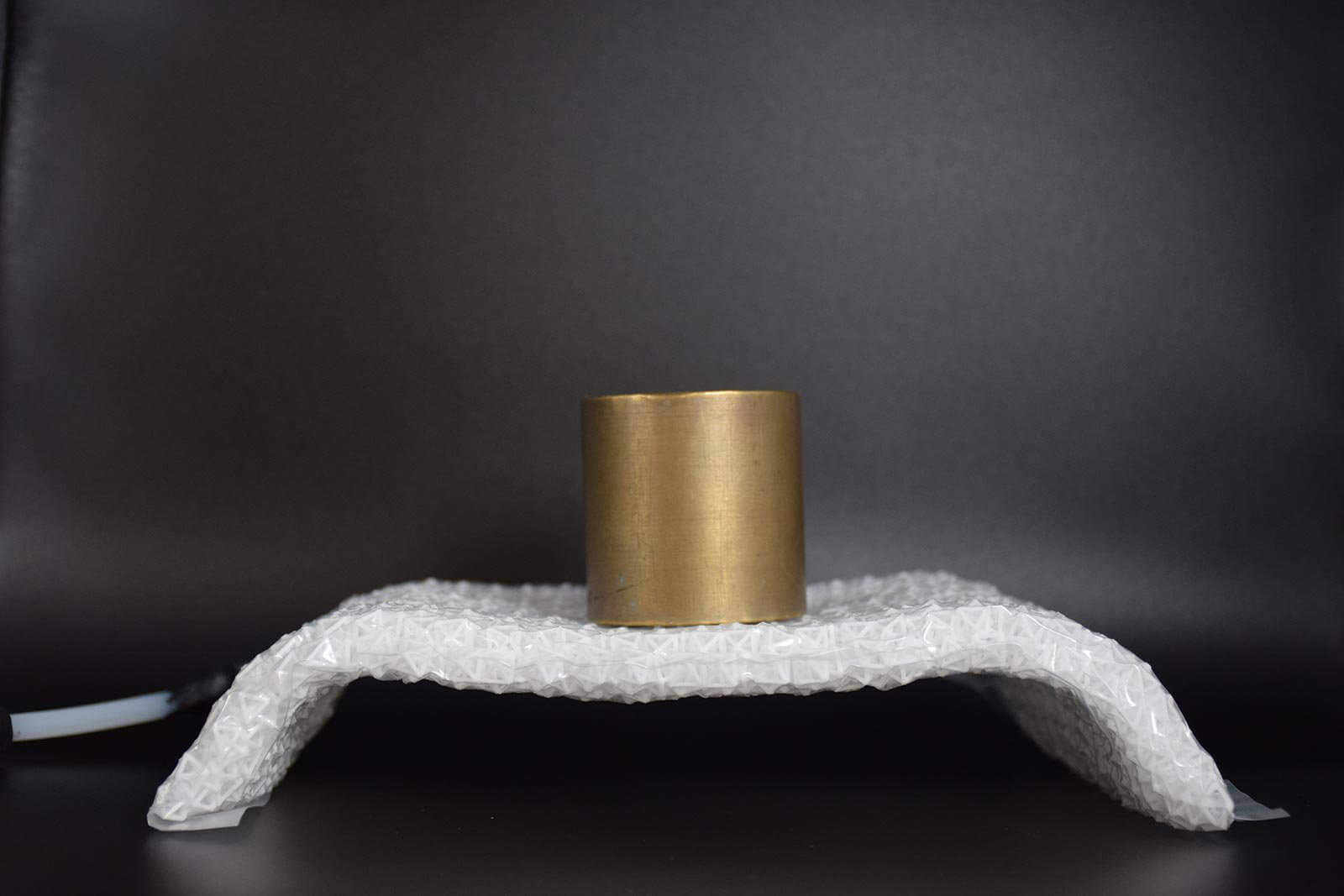

When formed into a flat, table-shaped structure and vacuum-locked in place, the fabric could hold a load of 1.5kgs, more than 50 times the fabrics’ own weight.

The nature of the octahedrons also means that the structure can lock into non-planar shapes as well, such as this bridge shape…

In another experiment, the researchers dropped a small, 30 gram steel ball onto the chain mail. The impact deformed the fabric by up to 26 mm when it was relaxed, but by only 3 mm when it was stiffened, a six times reduction in penetration depth.

“We wanted to make materials that can change stiffness on command. We’d like to create a fabric that goes from soft and foldable to rigid and load-bearing in a controllable way.” said Professor Chiara Daraio, Professor of Mechanical Engineering and Applied Physics at Caltech.

You can see a video of the chain mail in action in the video below.

“With an engineered fabric that is lightweight and tuneable – easily changeable from soft to rigid – we can use it to address the needs of patients and the ageing population, for instance, to create exoskeletons that can help them stand, carry loads and assist them with their daily tasks,” said Asst. Prof Yifan Wang from the NTU Singapore School of Mechanical and Aerospace Engineering,

“Inspired by ancient chain mail armour, we used plastic hollow particles that are interlocked to enhance our tuneable fabrics’ stiffness,” Asst. Prof Wang from NTU’s School of Mechanical and Aerospace Engineering

“To further increase the material’s stiffness and strength, we are now working on fabrics made from various metals including aluminium, which could be used for larger-scale industrial applications requiring higher load capacity, such as bridges or buildings.”

You can see a picture of one of the metal examples in the image below.

In future, the Caltech / NTU Singapore team aims to branch out into other materials, as well as research new (non-vacuum assisted) means of controlling the rigidity of the fabric structures, such as with magnetism, electricity or temperature.

If you’d like to know more about the chain mail (and maybe even design + print your own), you can access the paper over at this link.