Opdo and Luximprint have announced a new partnership that brings together AI-based optical design and additive manufacturing of optical components. The collaboration enables an end-to-end digital workflow for custom optics, allowing designs to move from natural-language input to final production in significantly shorter timeframes.

Opdo, known for its AI-powered optics design platform, will integrate Luximprint’s Printoptical® manufacturing process. The companies aim to streamline the development of advanced optics by reducing the time and complexity traditionally involved in both design and fabrication.

From AI-defined intent to 3D printed components

Opdo’s platform allows engineers to specify optical goals using natural language prompts. AI agents then generate and simulate manufacturable designs within minutes. By integrating Luximprint’s direct-from-file manufacturing method, the same designs can now be fabricated without tooling or manual translation steps.

“Opdo lets engineers describe what they want to achieve with light — and AI handles the rest,” says Stephan Kuehr, Founder and CEO of Opdo. “By adding Luximprint’s proven manufacturing technology, we connect AI design with digital fabrication in a way that fundamentally changes how optical products are developed.”

Expanding access to custom optics at scale

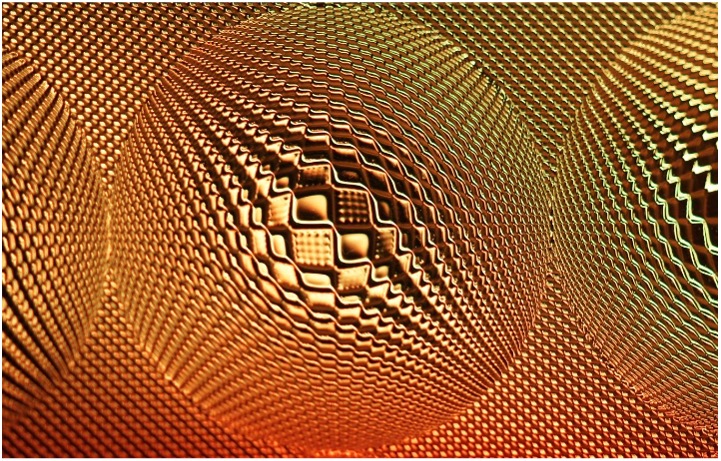

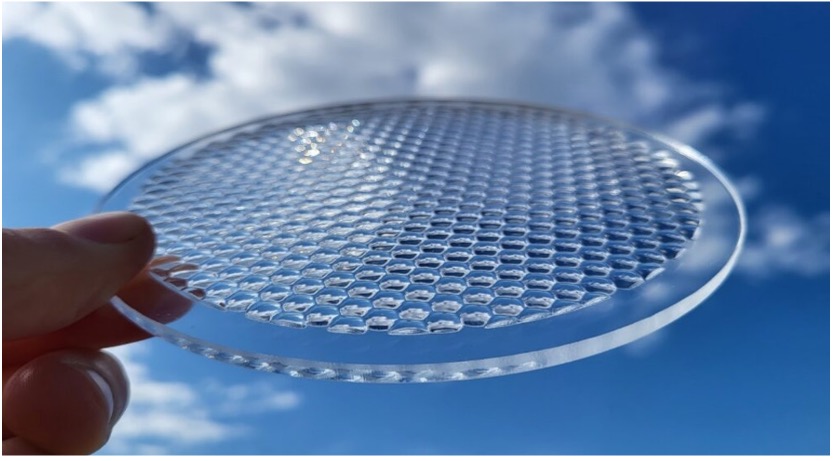

Luximprint’s Printoptical® process produces optical-grade surfaces directly from digital design files. It eliminates the need for traditional tooling and reduces lead times for functional and decorative optics. When combined with Opdo’s volumetric design and simulation capabilities, the system offers a practical solution for small-batch, iterative, or complex optical components.

“We’re excited to bring our Printoptical process to the Opdo platform,” says Marco de Visser, CEO of Luximprint. “This collaboration connects two complementary innovations — AI design and digital manufacturing — enabling custom optics to move from vision to physical reality faster than ever before.”

A growing digital fabrication network for optics

Luximprint joins a broader group of manufacturing partners integrated into the Opdo platform, which includes micro- and volumetric fabrication technologies such as Xolography and Nanoscribe. The platform is designed to offer engineers a streamlined, data-driven environment that covers the full range of optical development — from freeform lenses and light guides to microstructured surfaces.

With this partnership, Opdo and Luximprint aim to accelerate the deployment of custom optics across industries that require short lead times, high performance, and design flexibility.