One of the more laborious aspects of 3D printing is changing the buildplate, take out prints and set up the next one. If this is one of your pet peeves, OPENCREATORS has got your back. Their new BS210 printer is a kickstarter project with a built-in build plate changer. The company has a month to go on its campaign and has raised $17,406 of its $50,000 goal.

OPENCREATORS is based in both America and Korea. They were looking to create a system customised for small productions. Opencreators also found out that motor drives for existing 3D printers created inconsistent signals and unnecessary vibrations. They installed TMC motor drives to curb this problem. As a result, prints now have better surface quality and minimised wobbling.

The main features (as stated on the Kickstarter) are:

- 3D printer which can print continuously

- Reducing failure rates

- Industrial grade perfection and precise accuracy in measurements

- Supports water soluble support

- Full metal frame

- Wobble Free Design

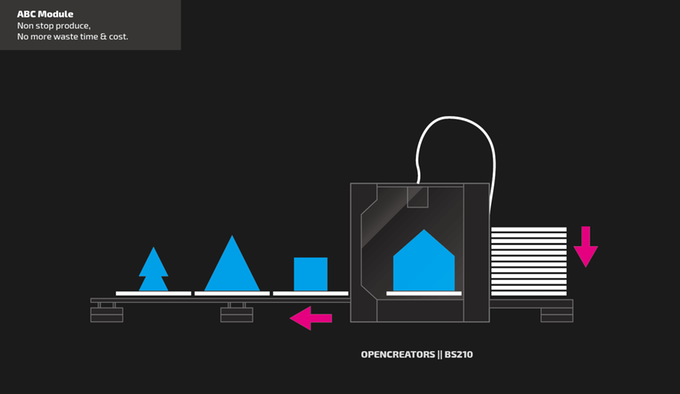

ABC Module

The core feature the company stresses in its description is the build plate changer. Their trademarked ABC module allows for nonstop printing through an automatic plate changing mechanism. The printer has a conveyer built style platform that stretches out from its build area. This sends out the completed prints while a system in the back puts down a new plate.

This is handy as it allows for 24 hour prints and users can cue multiple items and not have to worry about changeovers. It also allows for a process closer to that of a traditional assembly line. This is not surprising as OPENCREATORS have specifically cited that it was customised for small production. Future evolutions of such printers could definitely aim for industrial grade operations.

While the system is very handy, it does leave us with a few questions. Since by necessity it can’t have a closed chamber, does the BS210 calibrate for the outside temperature? Does it adjust its own heating with respect to heating changes around it?

Here’s a short video of the system in action.

360 SLP

Another prominent feature of the BS210 is the 360 SLP microscopic sensor. The sensor is recognises the curvature of the build plate and the XY access, relaying the information during the print. This enables the printer to ensure a stable first layer, making the whole print process smoother.

The 360 SLP allows adjusts for minute changes so that prints can be as even as possible. By implementing microscopic sensors to sense even the slightest curves, the module allows an even and consistent gap between the nozzle tip and the plate.

Pricing

There are a variety of pricing options available for the printer. It appears as though the prices for the final version are not finalised yet. In-depth pricing details can be found on the kickstarter page.