Oak Ridge National Laboratory seems to have all the best toys where it comes to testing 3D printing processes for metals, and the latest experiment at ORNL appears to reinforce that notion.

The researchers at ORNL have developed a robotic platform for studying the behavior of metal bonding during AM processes, which has been installed in their VULCAN engineering diffraction instrument at ORNL’s Spallation Neutron Source (SNS).

Read on to know more about the experiment.

OpeN-AM

The SNS facility is powered by a linear particle accelerator that uses beams of neutrons to study materials at the atomic scale.

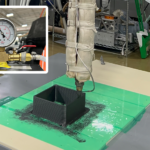

The 6-axis robot platform is named “OpeN-AM” (Operando Neutrons-Additive Manufacturing), which is their acronym signifying that the robot uses neutrinos to study the process while it is underway. The robotic arm is fitted with a welding torch for use during a wire arc-based AM process.

As the wire contacts the substrate, an electric current is applied that melts the wire and creates the bond to the substrate. It can also be fitted with a high power laser for melting a wire or powder feedstock into a melt pool.

The robotic AM arm also has a CNC companion stationed next to it, for subtractive processes, meaning that the OpeN-AM system has hybrid additive/subtractive capabilities.

The build table is fairly advanced also, and has multiple degrees of freedom to allow scanning from different angles, and is also equipped with cooling channels to alter the temperature of the part for studying the effects of heat during the process.

VULCAN

To scan the parts as they are built during experiments, the researchers will use the VULCAN engineering diffraction instrument. VULCAN fires a beam of neurons at the target area and measures the distance between atoms in metals as they’re exposed to extreme degrees of temperature and pressure, building a picture on how stress is forming. Multiple cameras are positioned around the area, so that temperature can be monitored during the process.

All of this process is automated, with everything synchronizing at the push of a button.

So far, the researchers have performed experiments on basic shapes, but the build area inside the VULCAN apparatus is large enough to accommodate parts as large as an engine.

“There’s only so much you can learn about a material after it’s processed using traditional characterization tools. The goal of the OpeN-AM project is to provide a new, more advanced way of characterizing the process that enables us to see inside the materials as they’re being produced,” said Alex Plotkowski, project lead at ORNL.

“Neutron experiments are a key component that allow us to observe and measure changes in the materials, such as temperature, how phase transformations are happening, and how the distributions of residual stresses are evolving. These insights are critical to optimizing the technology to make materials with improved performance.”

Accelerated with AI

Typically, experiments of this nature are time consuming, requiring collection of neutron data from various points around the object under study. Each location could take 30 seconds to collect the data, with the experiment needing to be paused multiple times. Often this could result in the experiment taking as long as 10 hours.

Thanks to the wonders of AI, the researchers are able to take a subset of data points which allow the machine where to collect data from next. The autonomous system then repositions the sample so the neutron beam can scan there.

It is a vastly optimized approach and allows researchers to make the best use of their limited experiment time. They also benefit from reduced data storage, as the system does not collect superfluous data when guided by the AI.

All in all, the algorithm can estimate residual stress characterizations in about one-third of the time that it would have taken before.