Researchers at the National Institute of Standards and Technology (NIST), KTH Royal Institute of Technology in Sweden, and other institutions have made a significant breakthrough in metal 3D printing.

By employing powerful X-rays generated by cyclic particle accelerators (synchrotrons) at two different facilities, the team was able to observe the internal structure of steel as it melted and solidified during 3D printing. This discovery enables professionals to better predict and control the properties of printed parts, making the technology more reliable and feasible for large-scale manufacturing.

Metal 3D printing processes are known for their material efficiency and ability to produce complex shapes, but they have been hampered by inconsistent results due to the rapid temperature changes causing varying crystal structures. Some of these structures can cause printed parts to crack prematurely, limiting the types of alloys that can be manufactured using additive processes.

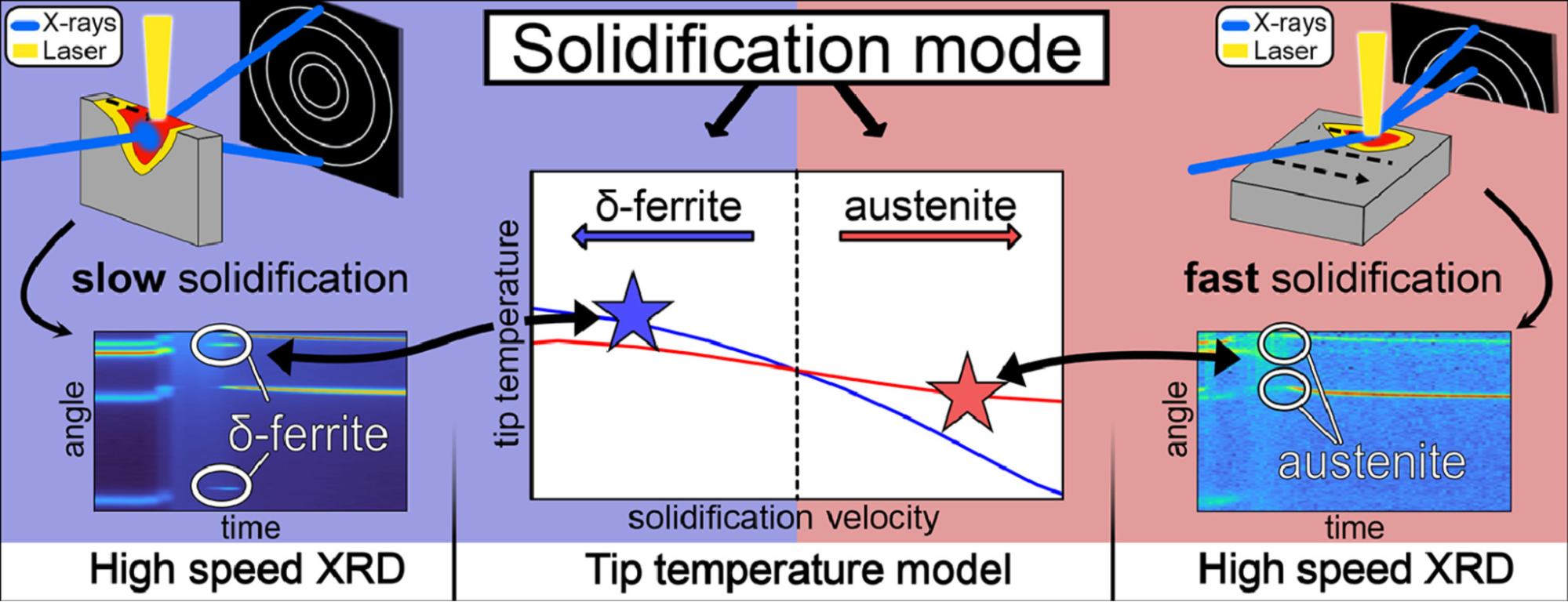

To overcome this challenge, the researchers examined how the cooling rates of metal, controlled by laser power and movement settings, influenced crystal structure. They then compared their findings to a widely-used computational model developed in the 1980s (a Kurz-Giovanola-Trivedi (KGT) based solidification model) which describes the solidification of alloys.

This model has mainly been used to study the solidification mode of hot-work tool steels, and until now, the applicability of this model to the unique context of 3D printing had been unclear. Thanks to the recent synchrotron experiments, the validity of the model for AM is now more apparent.

The team’s experiments demonstrated that the model and experimental data were in agreement, suggesting that the model can now be used to guide 3D-printing professionals in selecting the optimal cooling rates for the early solidification steps of the printing process. This will help ensure the desired crystal structure appears within the printed material, making metal 3D printing more predictable and reliable.

You can read the full research paper over at this link.

Come and let us know your thoughts on our Facebook, Twitter, and LinkedIn pages, and don’t forget to sign up for our weekly additive manufacturing newsletter to get all the latest stories delivered right to your inbox.