Florida-based rocket company Vaya Space has been awarded patents for their Vortex-Hybrid engine technology.

Unlike most rocket companies we look at on this website, Vaya Space is not only printing the rocket engines, but the rocket fuel grain itself.

Let’s look at what a Vortex-Hybrid engine is, and what the patents are for.

Hybrid Engine

Your average non-nuclear rocket comes in two general varieties, being of a solid fuel, or of liquid fuelled type.

Solid fueled rockets use a propellant where both the fuel and oxidizer is mixed into a resin, molded into a single cylindrical piece, and cured. This is called a propellant grain.

They are basically just like a giant firework, and like fireworks, once you light one, it’s not easy to put out.

While the cured grain makes handling, transportation and storage of such propellants relatively easy, the downside is that they lack the aforementioned ability to switch off/restart, and also lack any real throttle control.

Liquid-fuelled rockets on the other hand, are perfectly able to throttle, switch off, and restart, but they are generally bi-propellants meaning that two tanks are needed. Those individual bi-propellant components (fuel + oxidizer) tend to be either very nasty chemicals (for hypergolic/self igniting fuels) or very cold ones, needing cryogenic handling and piping systems on the roket. It’s very expensive to do this.

Plus when you add all the turbomachinery or pressure systems needed to move the fluid to the hot end of the rocket, it all gets very heavy, and nobody wants that on a rocket.

Liquid-fuelled rockets do offer the most bang for the buck however, in terms of thrust and specific impulse, which is why they will be the preferred choice for hoisting large amounts of payload into space for the foreseeable future.

So that leaves the hybrid, which as you can imagine, is a mix of solid and fluid. Generally in a hybrid motor, the fuel is the solid, and the oxidizer is some sort of oxygen rich liquid or gas such as nitrous oxide, or liquid oxygen in the case of Vaya Space.

For the solid part, Vaya Space is using recycled plastic. So it is, relatively speaking, “eco-friendly”.

The liquid segment in a hybrid motor can be throttled and switched off/on again, and the lack of oxygen in the fuel forces it to extinguish. It can then be restarted.

The vortex part of the Vortex-Hybrid design is named after the vortex flow of liquid oxygen that passes through the 3D lathe printed rocket engine.

This combines with Vaya’s other technologies to deliver more than 110 kN of thrust per engine, up to 350 seconds of ISP, and eliminates the instability and other issues that have plagued hybrid engines of the past decades.

Patents

Traditional propellant grains are poured into molds and then set. Several parties have demonstrated the feasibility of protected propellant grains. Additive manufacturing allows new geometries not permitted by molding processes, and so a more efficient burn can be achieved with AM.

Their first patent is related to their own in-house process for printing the grains with their recycled thermoplastic fuel.

The second patent is related to the vortex flow injection system itself, which allows oxygen to pass through the 3D printed rocket body for combustion with the fuel.

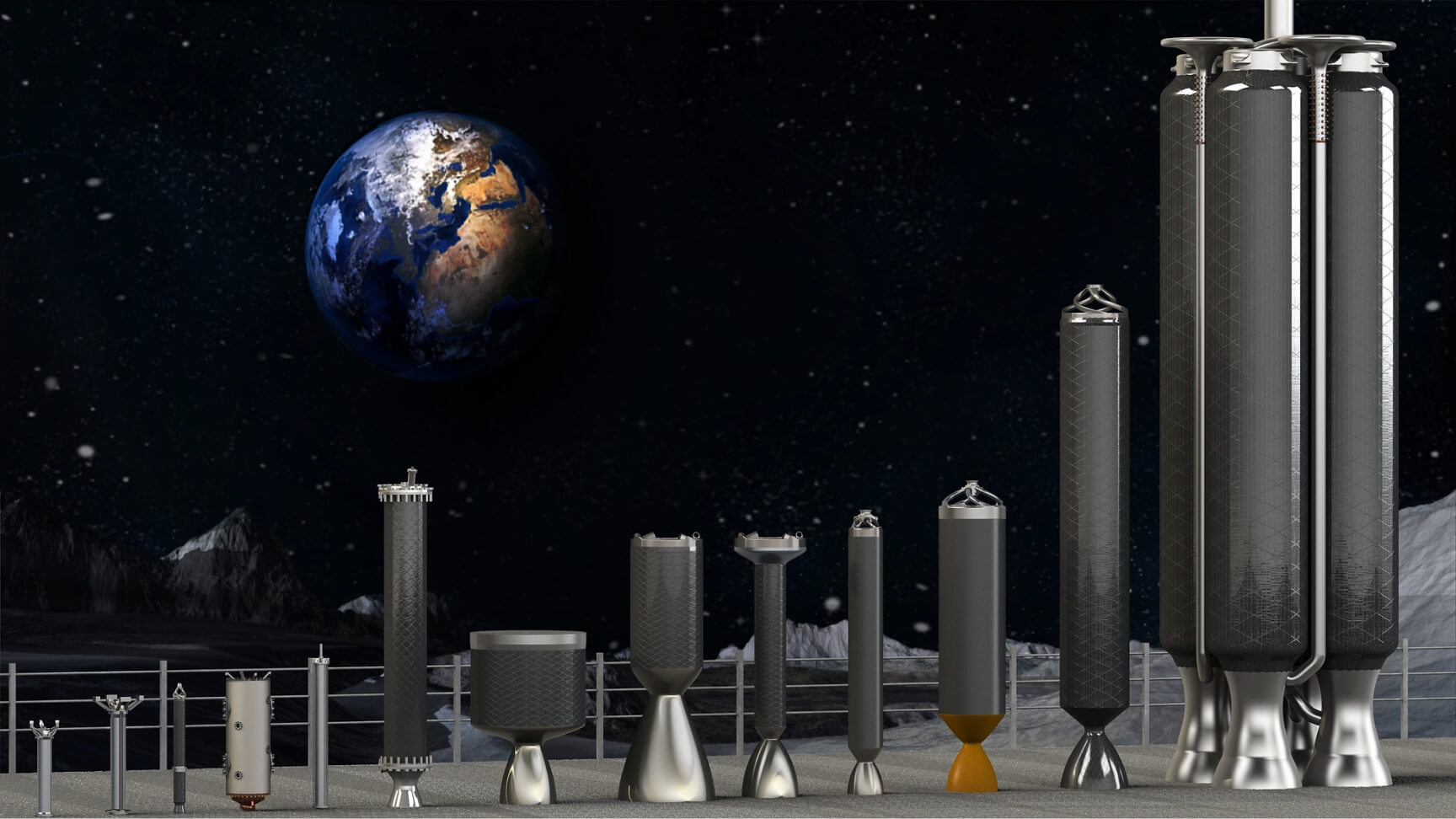

The printed grains, printed motor, various avionics and controls systems will all be integrated into a launch vehicle named “Dauntless”, which according to the company takes just one month to build and assembly for launch.

Dauntless will first launch sometime in 2023.

You can read more about their range of scalable hybrid rockets over at their website.