3D printing has changed manufacturing by offering design flexibility and faster product development. However, one challenge has been the strength of printed objects, especially in the Z direction. Objects printed with FDM processes are weaker in the Z-axis, a phenomenon known as anisotropy.

To address this, researchers in Germany have combined plasma with FDM printing to 3D print isotropic parts – that is, parts that have equal strength in all directions, much like a molded part.

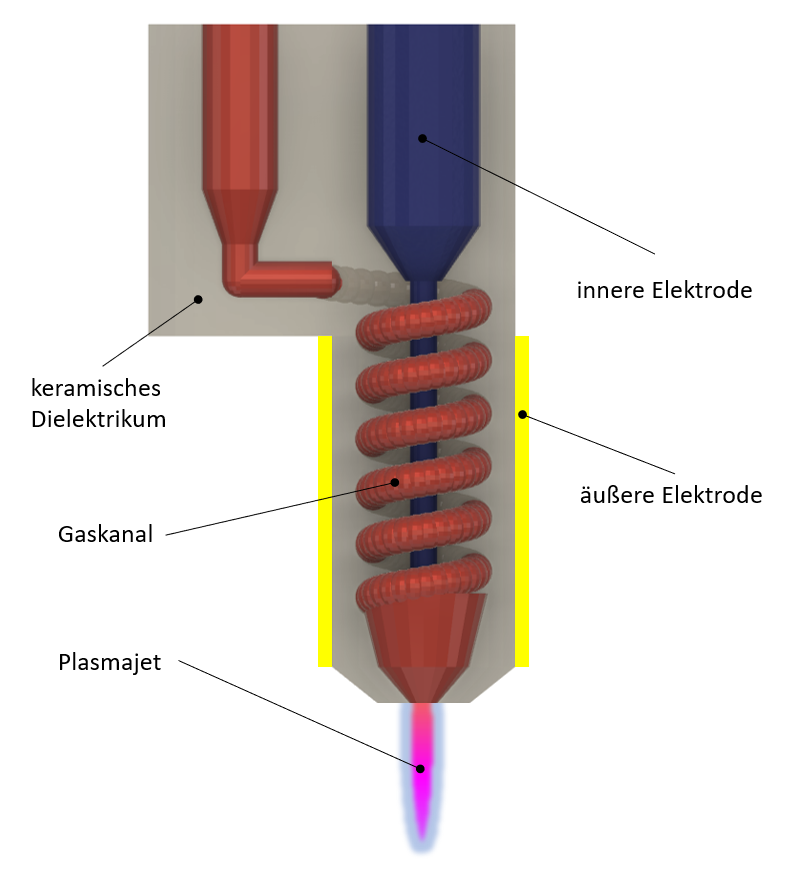

Alex Hilgenberg of Hilgenberg Ceramics, in collaboration with a German institute, has created a novel ceramic nozzle that performs plasma treatment on each printed layer. This process enables the creation of enhanced adhesive properties, surface sterilization, and conductive layers.

Plasma activation of plastic surfaces is a well-established technology, and the team adapted it for FDM 3D printing. The ceramic nozzle, made of high-purity aluminum oxide (Al2O3), was itself 3D printed, ensuring long-term dielectric properties and overcoming the limitations of typical nozzles.

The nozzle, attached parallel to the FDM nozzle, moves across the freshly deposited surface with a plasma jet after each layer. This effectively raises the temperature of the previous layer, allowing the subsequent layer to bond more efficiently with the layer beneath.

The applications of this technology are promising and are not limited to merely improving the strength of parts. For example, other benefits include the ability to clean contaminated surfaces for applying adhesives, surface sterilization, etching and roughening of fiber-filled filaments for surface activation, and deposition of layers for controlled adhesion properties in recycling.

The ceramic plasma nozzle’s increased durability and miniaturization potential make it an attractive option for various industries, including the semiconductor, sensor, actuator, and digital display sectors.

Come and let us know your thoughts on our Facebook, Twitter, and LinkedIn pages, and don’t forget to sign up for our weekly additive manufacturing newsletter to get all the latest stories delivered right to your inbox.