Wisconsin-based company PrintFoam wants you to stop designing plastic lattices with your fancy generative design and topology optimization software and start designing for foams instead.

Afterall, many of the lattices designed in these softwares are just trying to mimic the behavior of foams anyway, with their light densities and whatnot. So why not cut out the middleman and just churn out printed foams?

Why not indeed. Because PrintFoam wants you to know that with their newly launched resin-based printed foam system, they can churn out plywood sized sheets of foam in mere minutes, rather than hours.

And it’s not just sheets. It’s 3D printing so you can obviously do more complex geometries.

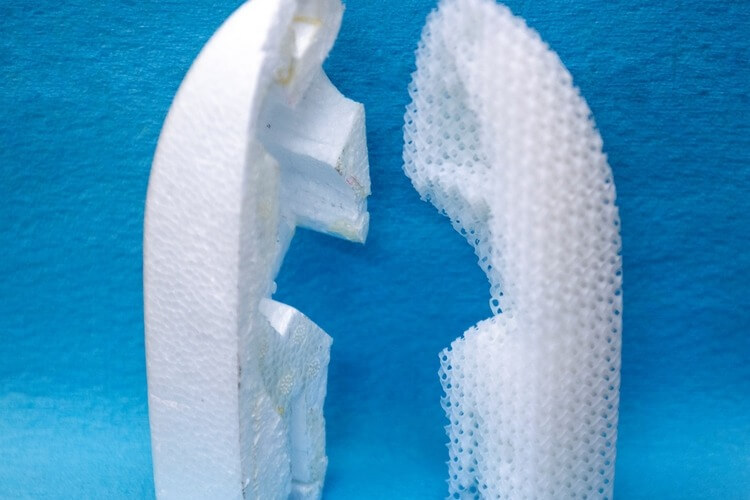

Check out the printed foam drone nose in the image below, designed to replace a traditional styrofoam version.

The system works by …uhhh….

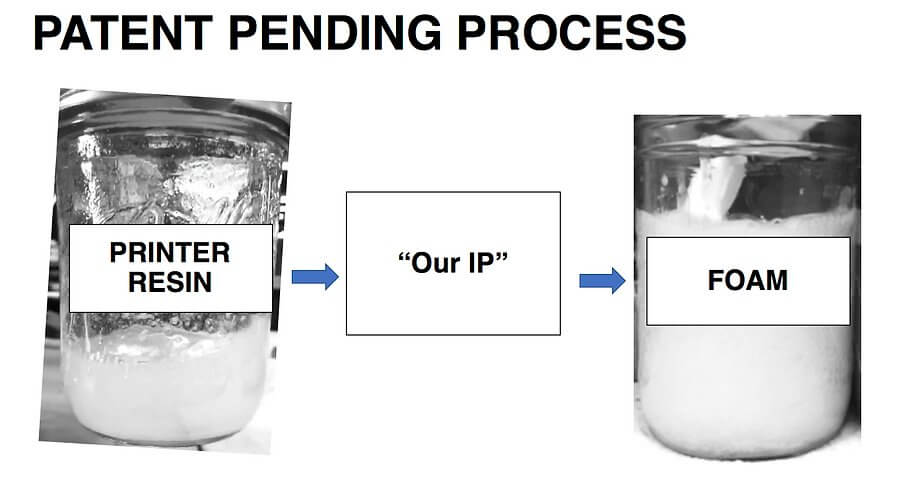

Actually, there isn’t much detail on how it works. In general it seems that there is some mechanical method to induce a foam in a typical printer resin, before the foam is cured with the light, much as a normal photopolymer curing process. Apparently existing SLA hardware can be retrofitted to perform this foaming task, so we expect the final version to be not too different than a usual SLA system.

The image below from the PrintFoam website gives slight detail on the process:

Lack of detail aside, the company has some solid engineering pedigree in terms of founders and backers, so that’s reassuring. Apparently they have happy customers in automotive, aerospace, defense, oil and gas, and construction sectors too (according to their website).

Founder and MIT-alumni Matthew Pearlson began his journey to this product release by modifying an SLA printer to print foams for lightweight aerospace applications. After nailing the process somewhat, and with some support from MIT’s Beaverworks and the MIT Sandbox Innovation fund, he has now developed the system into a large format system for the public.

The new PrintFoam system extends our ability to provide comprehensive solutions to our customers who are looking for ways to print a lot of material quickly without sacrificing resolution Matthew Pearlson, founder PrintFoam

“By using a combination of novel optical patterning techniques, along with ditching a standard vat printing process, we realized it would be possible to produce plywood sized sheets of 3D printed foam in a matter of minutes.”

The printer is undergoing some final beta testing right now, and the company are looking for collaborators to iron out any creases before a public release.

PrintFoam is already working with customers to explore novel approaches to noise mitigation, carbon sequestration, concrete construction, and more.

If you’d like to know more about the PrintFoam foam resin printer system, head on over to their website over at this link.

We will keep you updated as soon as they release some videos of the process.