Researchers from Université Laval in Canada have developed a method for 3D printing chalcogenide glass with a modified printer. 3D printed chalcogenide glass has many desirable properties. These properties are especially useful for developing glass components and optical fibers for low-cost sensors, telecommunications components and biomedical devices.

“3D printing of optical materials will pave the way for a new era of designing and combining materials to produce the photonic components and fibers of the future,” said Yannick Ledemi, a member of the Centre d’Optique, Photonique et Laser (COPL) group research team at the university. “This new method could potentially result in a breakthrough for efficient manufacturing of infrared optical components at a low cost.”

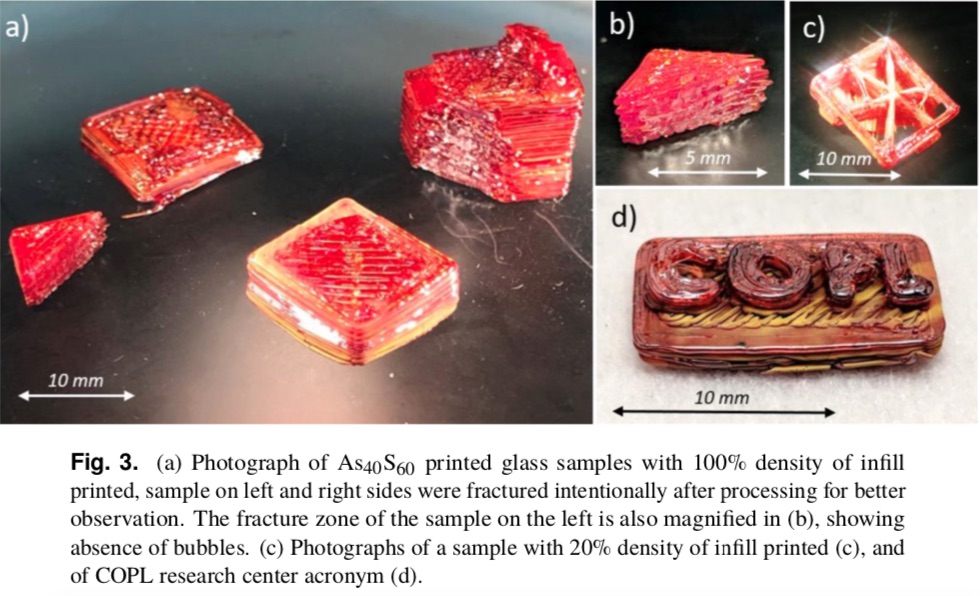

The researchers produced actual chalcogenide glass filaments with similar dimensions to run-of-the-mill ones. They also programmed the printer to create two samples with complex shapes and dimensions. Although the process is still ironing out some kinks, the researchers believe that it could be used for producing infrared glass components or fiber preforms.

Modding a Printer For Chalcogenide Glass

Another reason this discovery is significant is the relative simplicity of the equipment. While many projects require making a custom build industrial 3D printer, the researchers were able to modify an ordinary desktop 3D printer for their glass printing purposes. This indicates that the process probably won’t require intense equipment of some sort.

Since printing chalcogenide glass requires more heat (330 °C), the researchers modded the extruders. Their printer now has two E3DV6 extruders close to each other, with the proximity adding to the heating zone length. Additionally, due to its FDM printing-based design, it already had drive wheels. The researchers modified these to increase the load and enable glass filament feeding.

To obtain the appropriate chalcogenide glass viscosity for extrusion, both extruders had to be manually adjusted by varying the operating tension and current of the tension controller. However, the filament feeding speed and the print bed displacement were automatic. The researchers used a nozzle diameter of 0.4 mm during printing. They recommend using a substrate a material with a similar thermal expansion coefficient to limit thermal stresses. Admittedly, it’s not all quite so user-friendly. The researchers also recommend working under a chemical fume hood and using a gas tight protection enclosure. Printing chalcogenide glass does, after all, release some pretty powerful and dangerous vapors.

The researchers state that their future work will focus on improving thermal management and process conditions. They thus hope to increase the mechanical robustness and optical quality so they can produce glass preforms for fiber drawing.

Featured image courtesy of Université Laval. The full study is also available here.