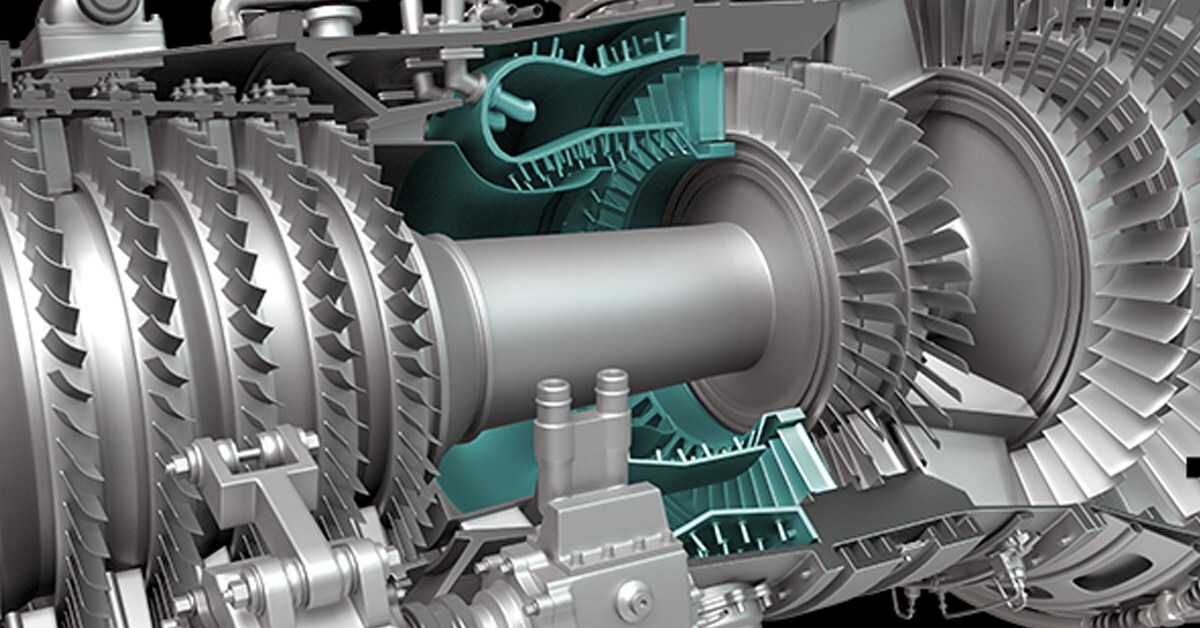

QuesTek Innovations has partnered with a global niobium producer to develop a high-temperature alloy designed for additive manufacturing. The project targets aerospace and energy industry applications, with input from GE Vernova and Technetics Group to align the material with manufacturing requirements across propulsion, power generation, and advanced equipment sectors.

The collaboration aims to address supply chain disruptions and materials scarcity affecting advanced manufacturing industries. The new printable alloy is intended to reduce reliance on traditional manufacturing processes while enabling faster production of high-performance parts for high-temperature applications.

QuesTek says the alloy design will eliminate long tooling lead times and forge limitations that currently slow development in high-temperature uses. The material is being developed to provide manufacturing flexibility as companies navigate supply chain challenges and shifting market conditions.

The project includes sustainability considerations, with the alloy designed to support more efficient engines and reduce manufacturing waste. This approach aligns with industry goals for lower emissions and improved system efficiency in energy applications.

The multi-phase development process uses QuesTek’s ICMD design platform to move from digital simulation to physical validation. QuesTek specializes in computational materials engineering and claims its Materials by Design technology reduces development time and costs while increasing material performance compared to traditional methods.