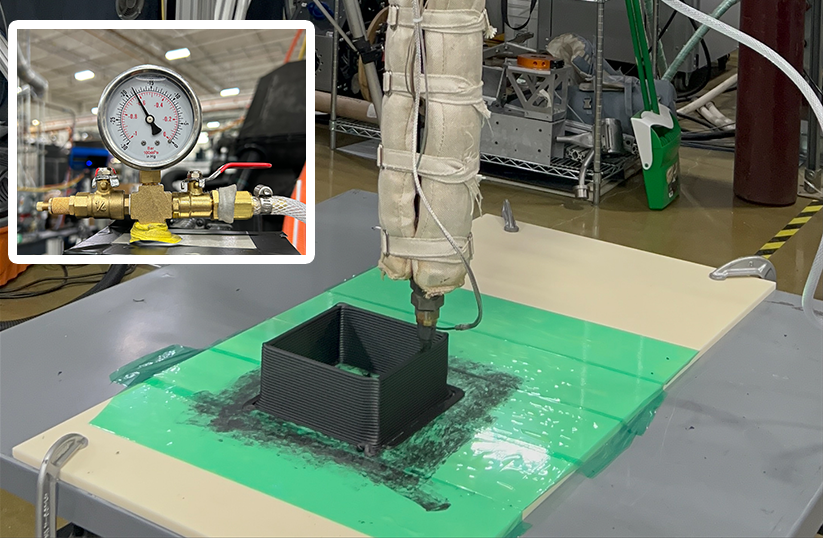

Oak Ridge National Laboratory (ORNL) researchers have created a vacuum-assisted extrusion technique that reduces internal porosity in large-scale 3D-printed polymer parts by up to 75%. The method addresses a significant limitation in large-format additive manufacturing (LFAM), which has struggled with internal voids that compromise the structural integrity of printed components. This advancement could improve the adoption of LFAM technology across aerospace, automotive, and defense tooling applications.

The technique integrates a vacuum hopper during the extrusion process to remove trapped gases in fiber-reinforced materials. These materials, commonly used in LFAM for their stiffness and low thermal expansion, typically contain intrabead porosity that affects final part quality. Testing showed the new system reduced porosity to under 2%, regardless of varying fiber content.

“Using this innovative technique, we are not only addressing the critical issue of porosity in large-scale polymer prints but also paving the way for stronger composites,” said ORNL’s Vipin Kumar. “This is a significant leap forward for the LFAM industry.”

The current implementation is designed for batch processing of materials. However, ORNL has already developed a patent-pending concept for continuous deposition systems, which will be explored in future research initiatives.

This development represents meaningful progress in overcoming one of the key technical challenges facing large-scale 3D printing. By addressing porosity issues, the technology could help improve the strength, durability, and performance of large printed components for industrial applications.

Source: ornl.gov