Chemists from Saarland University have developed a world-first technique that can 3D print complex structurally colored objects. By modifying starting materials typically made of common polymers such as polystyrene or poly(ethyl acrylates), the researchers have created “perfect particles” with a hard center and a soft shell that can be processed using a 3D printer.

Structural colors can be controlled by numerous means such as changing temperature, modifying pH, or applying an electric voltage to the material, making them completely harmless and resistant to fading.

Until now, these materials have been restricted to ultra-thin films, but the ability to shape them into 3D objects has opened up a wide range of potential future applications such as anti-counterfeiting technology or versatile measurement sensors.

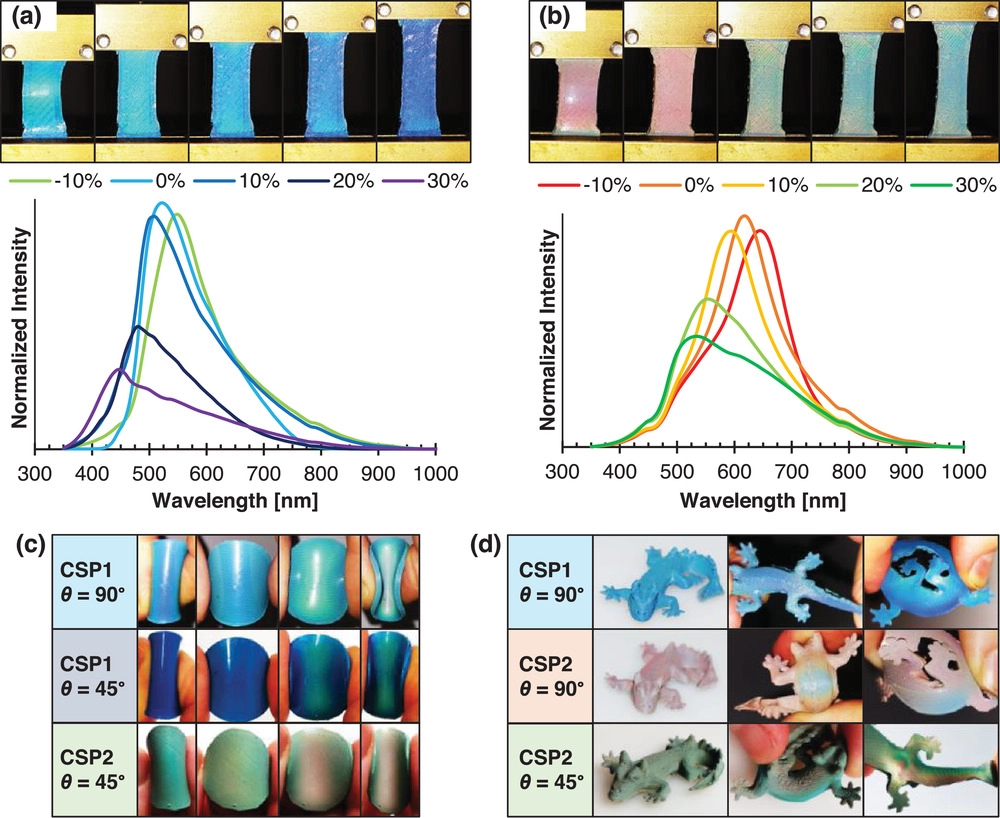

These particular materials have been demonstrated to change color when tensile or compressive forces are applied. You can see this in the graphic below.

The particles can be shaped to have highly specific properties and are easy to form. The technique required the researchers to modify the flow properties and thermal properties of the powdery starting material. The researchers hope their method will lead to the development of new and practical applications for these shimmering structurally colored objects.

You can read the research paper in full over at this link.

Come and let us know your thoughts on our Facebook, Twitter, and LinkedIn pages, and don’t forget to sign up for our weekly additive manufacturing newsletter to get all the latest stories delivered right to your inbox.