Carbon fiber reinforced polymer (CFRP) composites are great. As long as they are made with continuous fibers.

When you start chopping these carbon fibers up and mixing them with a thermoplastic base, most of the benefits of a CFRP structure are lost. In the case of chopped fiber filament, the fiber is no longer carrying the load..the weaker polymer matrix is. The carbon fiber is effectively just filler.

So any new method of 3D printing with continuous carbon fibers is of interest to us. If you’re going to print with carbon fiber, may as well reap all the benefits – not just the finish.

This new method devised by a research team at the University of Delaware has demonstrated a method for using a thermoset polymer matrix for their 3D printed composites, as opposed to previous composite printers which have generally used thermoplastic polymer as a matrix.

What is the difference between thermoset and thermoplastic, and why is it significant? We will tell you.

Thermoset vs Thermoplastic

For the benefit of this post, all we need to know is that a thermoplastic (such as ABS) when heated, will melt. And when it cools, it will harden. This cycle can be repeated over and over, and the polymer can be remelted and reformed many times without any physical changes occurring to the material.

A thermoset plastic, in basic terms, will permanently set into a solid when it cools. It is not reversible.

Some CFRP applications are fine with thermoplastics. Others, which may be exposed to a higher range of temperatures (aerospace), may require a polymer matrix that won’t melt when it heats up, so they opt for thermoset CFRP systems. Thermosets also have good resistance to fatigue, which is also attractive in aerospace applications (and also sporting goods).

Currently, 95% of aerospace CFRP components use thermoset pre-pregs…so you can see that there may be a demand for thermoset printing in that market.

Continuous Thermoset Printing

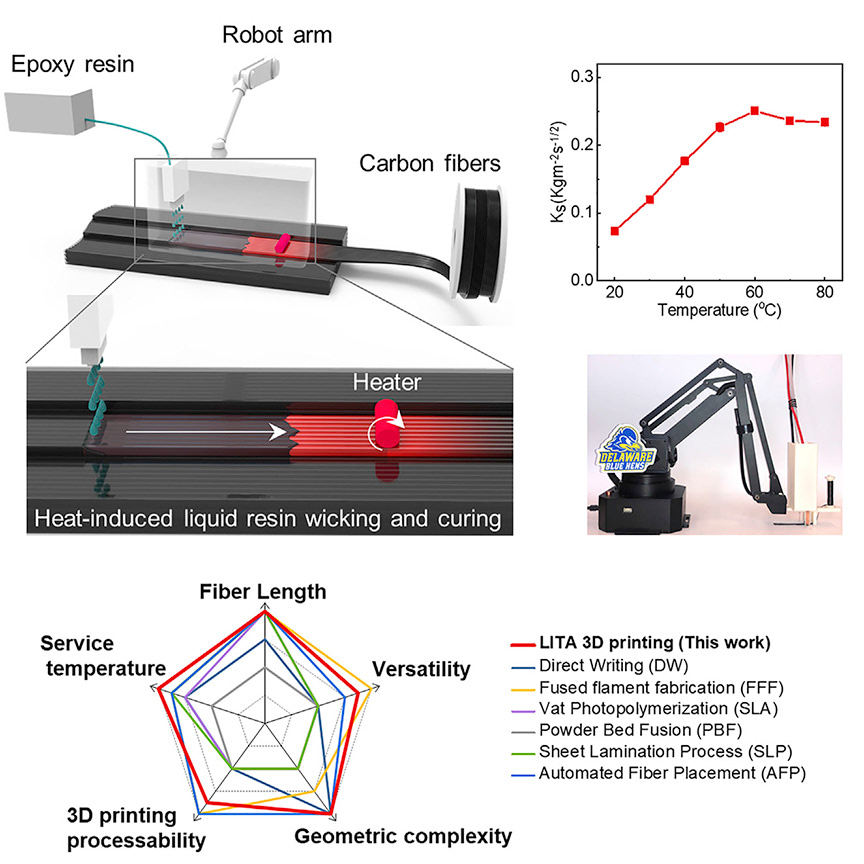

The research team from the Center for Composite Materials (CCM) at University of Delaware recognizes this need for thermoset CFRP printing, and so has developed their Localized In-plane Thermal Assisted 3D printing system (a.k.a “LITA”). It uses a unique printing head and automated robot arm. With this system the team is able to guide the fibers into the required shape, and guide the flow of the liquid polymer by manipulating the temperature of the fibers with a Joule heater. This allows the thermoset resin to flow and wick into the channels between the fibers, before curing to create strong, thermally stable 3D structures.

The team has published a paper on their method, titled “Dynamic Capillary-Driven Additive Manufacturing of Continuous Carbon Fiber Composite” which should give you some indication of the mechanism at work here.

In technical terms, according to the paper:

“The underlying concept of the LITA technique is based on a continuous capillary effect or wicking,which is enabled by a moving thermal gradient along the carbon fiber surfaces, to facilitate the flow of liquid polymer into the tube-like space between neighboring carbon fibers followed by curing of the polymer resin from the heated fiber surfaces to the surrounding space.”

Traditionally fabricated CFRP composites require many hours of post curing. The controlled rapid-curing of the LITA system does not, and therefore there are huge energy savings made by use of this system.

In addition, traditional CFRP is thus-far limited in terms of the geometries allowed by the process. This process, if developed further, may find usage in aerospace, automotive, sports goods, or any other industry that requires light, stiff, fatigue-resistant components that won’t melt during operations.