Optical lenses are essential in many fields, from microscopy to machine vision systems. Traditional lens manufacturing is a multi-step process involving grinding, polishing, molding, and coating, which is time-consuming and costly, particularly for customized, low-volume production.

Additive manufacturing has emerged as a promising alternative for fabricating optical components. Techniques such as material jetting and vat photopolymerization (VPP) offer high precision and speed, but achieving the necessary smoothness for high-quality lenses remains challenging due to the layer-by-layer nature of 3D printing.

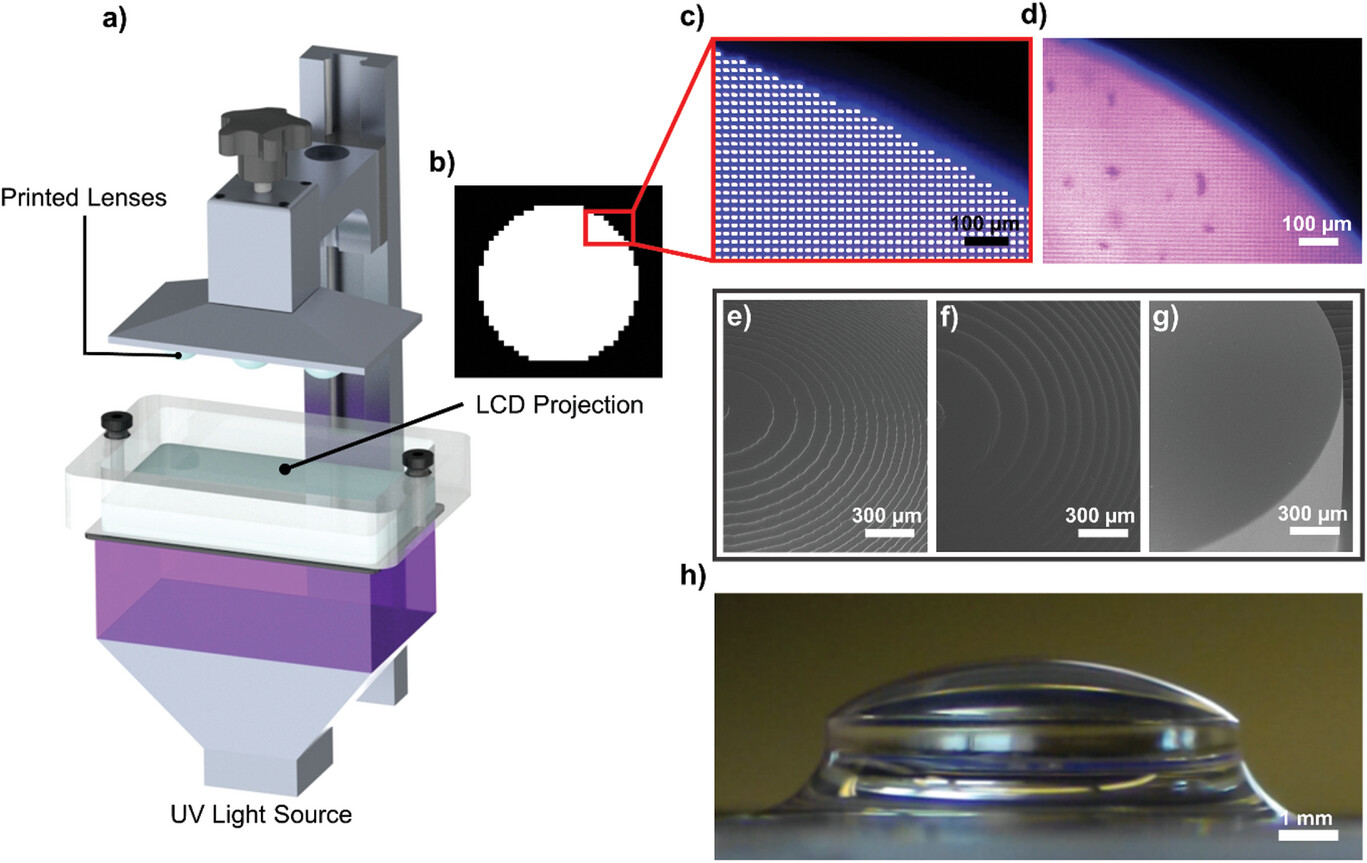

Researchers from Purdue University have addressed these challenges by developing a VPP-based lens printing process that minimizes lateral and vertical stair-stepping defects. This process integrates unfocused image projection and precision spin coating. By slightly defocusing the curing image during printing, lateral pixelation is reduced without sacrificing build size. The subsequent spin coating smooths vertical steps.

Their research, published in Advanced Functional Materials, demonstrates that the precision spin coating process, previously considered unreliable on curved surfaces, can be accurately controlled and predicted. The coating profile remains unaffected by the printed staircases if enough liquid is applied, allowing the surface to be treated as smooth. The coating thickness can be controlled within 1 μm.

The researchers successfully fabricated multi-scale lenses, ranging from 3 to 70 mm in diameter, with surface roughness less than 1 nm and profile accuracy within 1 μm. The lenses exhibited excellent optical performance, including high modulation transfer function (MTF) resolution and minimal distortion.

This method could transform lens manufacturing by enabling rapid, low-cost, customizable production of high-quality optical components, potentially benefiting fields such as custom eyewear, scientific instrumentation, and medical devices. Further research will explore optimizing printing parameters, new materials, and multi-material lenses for enhanced optical functions.

You can read the full research paper, titled “3D Printing of Optical Lenses Assisted by Precision Spin Coating” over at this link.

Source: nanowerk.com