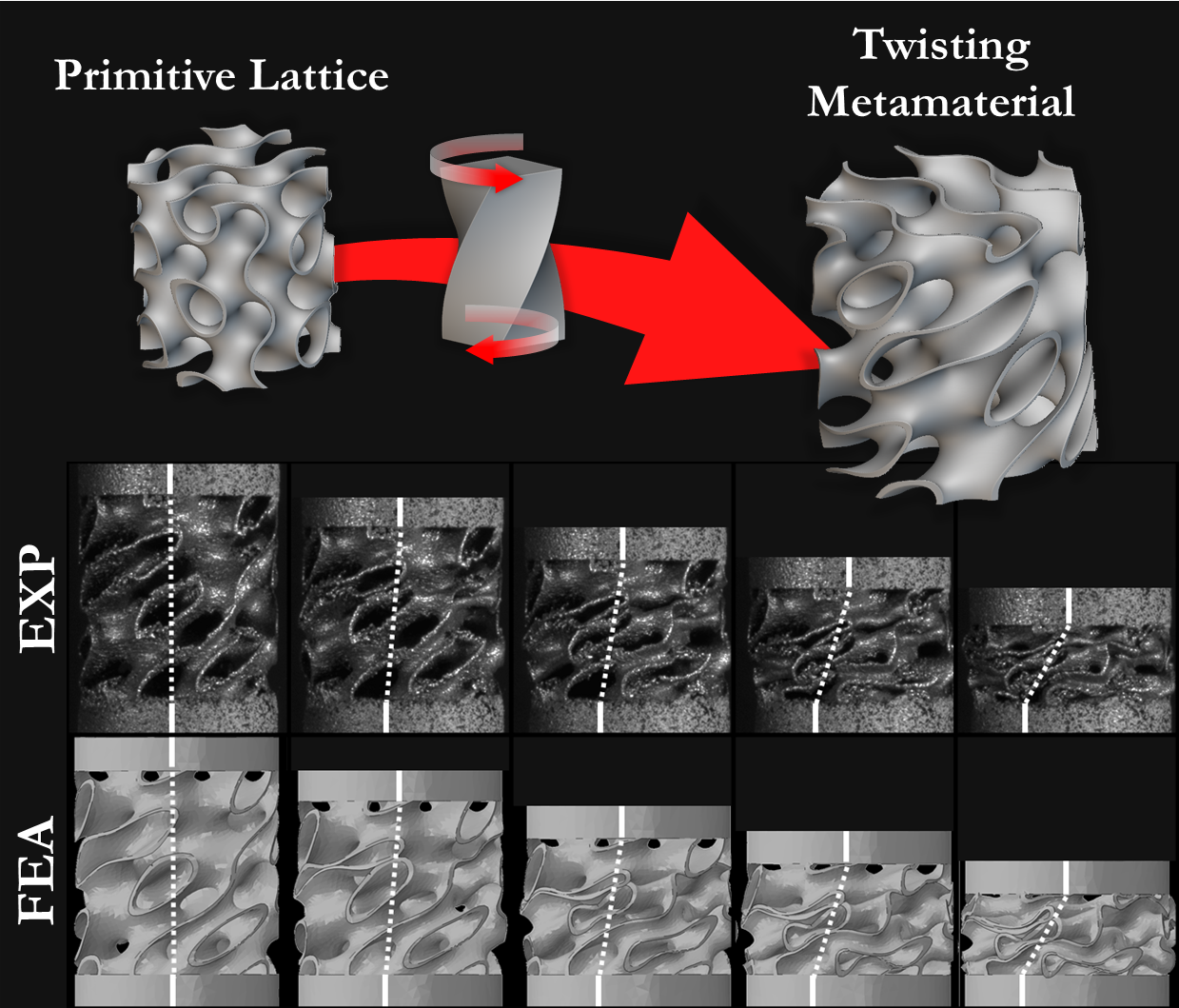

Researchers from universities in Scotland and Italy have developed a new 3D-printed metamaterial that can adjust its protective properties based on impact type and severity. The material features a gyroid lattice structure that twists when compressed, offering potential applications in automotive and aerospace crash protection.

The metamaterial differs from conventional protection materials like foams or crumple zones, which provide fixed resistance levels. Instead, the new material’s response can be mechanically controlled by adjusting how much it’s allowed to twist during compression. This allows it to provide either rigid protection for severe impacts or softer cushioning for lighter collisions.

Laboratory tests showed the material’s adaptability across three configurations. When prevented from twisting, it absorbed maximum energy at 15.36 joules per gram. Free twisting reduced energy absorption by approximately 10 percent, while forced over-twisting decreased it by 33 percent. The material is manufactured from steel using additive manufacturing processes.

Professor Shanmugam Kumar of the University of Glasgow’s James Watt School of Engineering, who led the research, explained the material’s advantages. “The protective materials used in most vehicles today are static, designed for specific impact scenarios and unable to adapt to varying conditions,” Kumar said. He noted that the material requires no complex electronics or hydraulics to adapt, instead relying on mechanical rotation control.

The research, published in Advanced Materials, involved collaboration with Italy’s Polytechnic University of Marche, University of L’Aquila, and National Institute for Nuclear Physics. The team used computational models and micro-CT reconstructions to account for manufacturing imperfections and predict the material’s behavior under different conditions.

Source: gla.ac.uk