Researchers from the universities of Heidelberg and Stuttgart have developed a new type of ink that enables 3D printing of conducting polymers capable of changing color through electrochemical manipulation. The ink uses digital light processing (DLP), a light-based 3D printing method that builds objects layer by layer through selective UV light exposure.

The research teams created a methacrylate-based ink containing redox-active carbazole groups. These units allow the polymer chains to donate or accept electrons, making them electrically conductive and able to change color based on their oxidation or reduction state. “Although the technology has already been successfully used in dentistry, for example, until now DLP printing of conducting polymers for applications in optoelectronics has been challenging,” explains Prof. Dr Eva Blasco from Heidelberg University’s Institute for Molecular Systems Engineering and Advanced Materials.

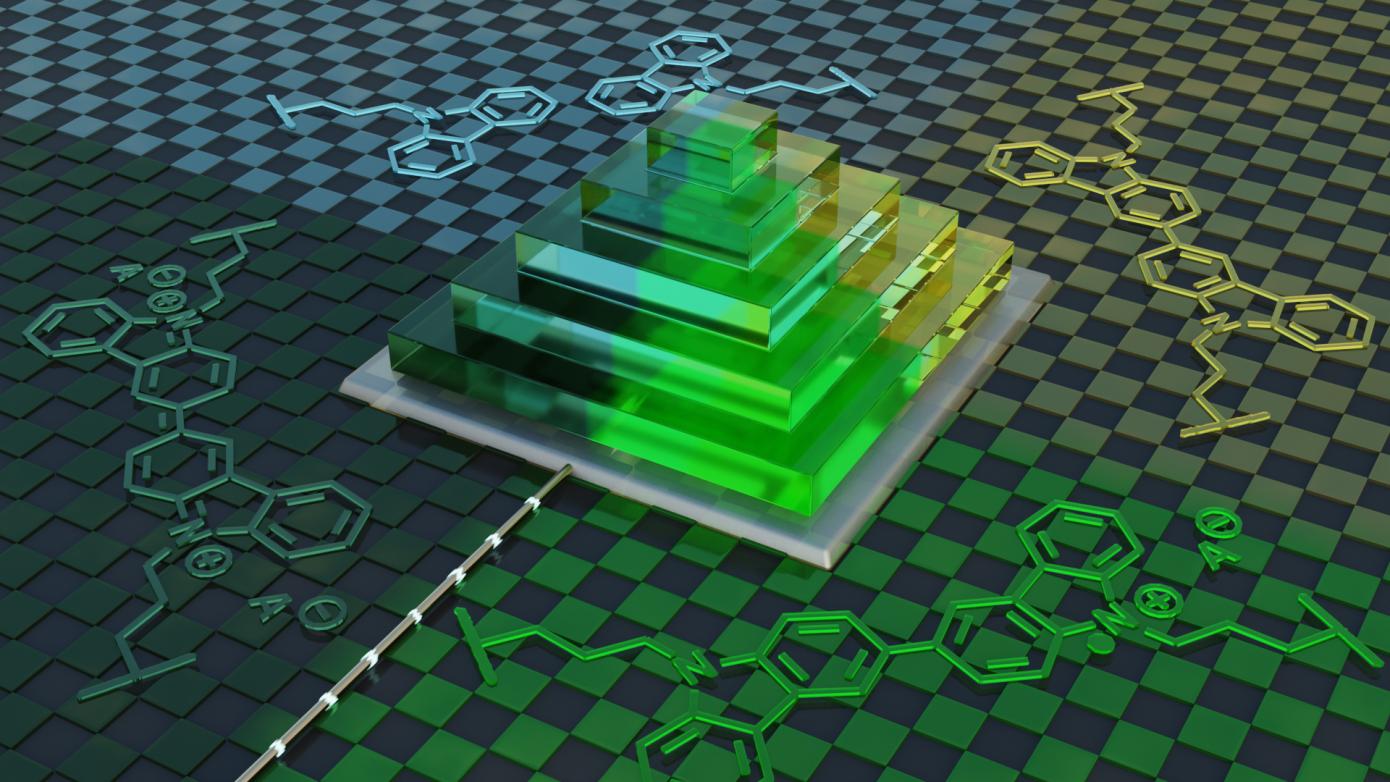

Using the new ink formulation, the researchers successfully printed two-dimensional pixel arrays, checkerboard patterns, and a multi-layered three-dimensional pyramid. The initially transparent structures changed from light green to dark green and ultimately to black through electrochemical stimulation. “This process is completely reversible and can be controlled down to the pixel level depending on the structure. Control in the third dimension, i.e., with respect to the architectures’ height, is especially exciting,” adds Sabine Ludwigs from the University of Stuttgart.

The research was conducted within the “Mixed Ionic-Electronic Transport: From Fundamentals to Applications” Research Training Group, supported by both universities and funded by the German Research Foundation. According to the researchers, this combination of high-resolution 3D printing with redox polymers could enable new manufacturing approaches for pixel displays or actuators for soft robotic applications. The results appear in the journal “Advanced Functional Materials.”

Source: uni-heidelberg.de