From biomedicine to soft robots discoveries, hydrogels have opened a whole new world for 3D printing applications. They’ve been around for a while, providing crucial research into cell regeneration and tissue growth and so much more. Now, a new research project between Singapore University of Technology and Design (SUTD) and the Hebrew University of Jerusalem (HUJI) is looking to add a high flexibility, stretchable hydrogel to the mix. Their findings may provide a far more resilient and malleable version of hydrogels, allowing for higher capabilities in many different fields.

Hydrogels consist of hydrophilic networks of polymeric chains that, as the name suggests, can retain water. This gives them all sorts of desirable properties and the ability to contain structures like biological scaffolds within themselves. Basically, their usefulness cannot be overstated and they form the backbone of a lot of modern findings. The problem is that modern hydrogels have low geometric complexity and relatively low fabrication resolution. As a result, this hampers their applicability in various fields of research.

With the invention of these far more stretchable hydrogels, researchers can circumvent these problems. The higher resolution and malleability allows for increased applications in soft robotics, transparent touch panels and flexible electronics. The gels also show excellent biocompatibility, according to the researchers, and can serve as a great source of printing applications.

Applying Stretchable Hydrogels

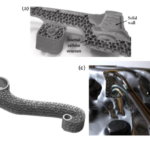

The hydrogels the researchers developed are UV-curable, making them suitable for some very complex structures. UV-curable, flexible hydrogels could also have applications in vascular networks, porous scaffolds, meniscus substitutes and a lot more. The printed hydrogel sample can stretch by up to 1,300 percent. Additionally, the compatibility of these hydrogels with DLP-based 3D printing technology allows for the fabrication of hydrogel 3D structures with resolutions up to 7 micrometers.

The stretchable hydrogel can even form strong interfacial bonding with commercial 3D printing elastomers allowing for the formation of hybrid structures such as flexible electronics boards. Clearly, there are tons of applications and the research is only just scratching the surface of this new finding.

If you’re interested in the research, you can read it here. It presents some very interesting results and promises future concepts that may just alter the way we think about flexible manufacturing.

Featured image courtesy of Singapore University of Technology and Design (SUTD) and the Hebrew University of Jerusalem (HUJI).