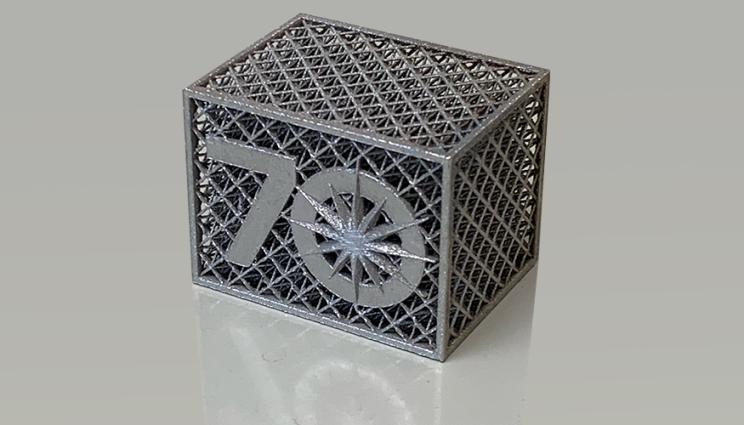

Researchers at the Lawrence Livermore National Laboratory (LLNL) have developed a real-time method for detecting and predicting strut defects in 3D printed metal lattice structures.

The team used monitoring, imaging techniques, and multi-physics simulations during the laser powder bed fusion (LBPF) process to detect and predict missing struts and other defects. By monitoring the thermal emissions from the melt pool during printing, the researchers were able to predict whether a strut was present or missing with an accuracy of over 94%.

They used a combination of a photodiode, a pyrometer, and thermal imaging to monitor the printing of a metallic micro-lattice structure, both normal struts and intentionally defective “half-struts” were printed, with the researchers measuring the thermal emissions from the melt pool.

“At the moment, we are capable of detecting defects that span multiple layers, but in the future, new methods will be developed to identify defects within a printed layer,” said Jean-Baptiste Forien, lead author and LLNL staff scientist.

“This will allow a dynamic reaction and potentially the suppression of the defect before resuming printing of the rest of the build.”

The method provides the ability to detect and potentially suppress defects before resuming printing of the rest of the build.

You can read the full research paper, titled “Detecting missing struts in metallic micro-lattices using high speed melt pool thermal monitoring” in Additive Manufacturing Letters, over at this link.

Come and let us know your thoughts on our Facebook, Twitter, and LinkedIn pages, and don’t forget to sign up for our weekly additive manufacturing newsletter to get all the latest stories delivered right to your inbox.