Engineers and chemists at Lawrence Livermore National Laboratory (LLNL) and Meta have collaborated to develop a 3D printed material that emulates the properties of biological tissues. This advancement has the potential to significantly impact the field of wearable technology and enhance the concept of “augmented humanity.”

Published in the journal Matter, their research introduces a unique 3D printable resin that utilizes light to create smooth stiffness gradients, replicating natural transitions found in biological structures, such as the junction between bone and muscle. This addresses a significant challenge in creating more realistic wearables: the mechanical disparity between soft tissues and rigid electronic components.

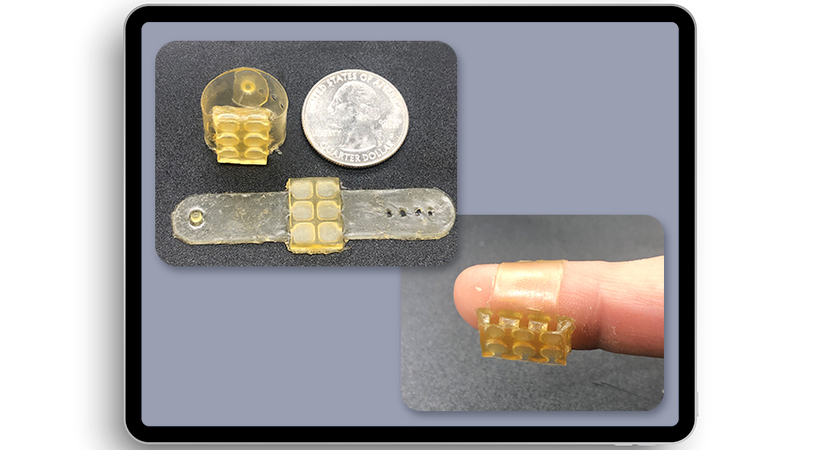

The team demonstrated the material by designing a 3D printed wearable braille device capable of translating text messages into braille instantly. By adjusting the light intensity during the Digital Light Processing 3D printing process, they achieved continuous mechanical gradients from soft to stiff within a single resin system.

“A beautiful feature of additive manufacturing is that we can create these impossible structures, but also we are somewhat limited in terms of the material properties — we only have a certain amount of material that we can pick from,” lead author and LLNL engineer Sijia Huang.

“One of the initial motivations was, ‘what if we could have the same resin system and replicate the engineered plastic systems effortlessly by merely adjusting the light intensity?’ That would save a significant amount of time and effort for engineers, particularly when incorporating new properties of materials.”

This research opens possibilities for crafting wearable devices with adaptable material properties, with potential applications in soft robotics, energy-absorbing materials, and wearable electronics.

Crucially, the material displays robust stability under both light and ambient conditions, distinguishing it from traditional plastics. This development represents a significant step forward in the realm of variable-stiffness polymer materials with long-term durability.

You can read the full research paper, titled “One-pot ternary sequential reactions for photopatterned gradient multimaterials” over at this link.

Come and let us know your thoughts on our Facebook, Twitter, and LinkedIn pages, and don’t forget to sign up for our weekly additive manufacturing newsletter to get all the latest stories delivered right to your inbox.