One of 3D printing’s core issues is weak interlayer bonding of 3D prints. Now, researchers in Texas have come up with a means of strengthening filament through application of microwave radiation. As a result the prints come out stronger by a factor of 275%.

The researchers made changes to the filament so that it could maintain temperatures for longer stretches. The method requires coating the filament with carbon nanotubes to locally induce radiation providing longer heating periods. The researchers have dubbed the method LIRF.

What is LIRF?

LIRF stands for Locally Induced Radio Frequency. It uses the heating properties of carbon nanotubes when in reacting to microwave radiation to improve print strength. The researchers coated the filament with multi-walled carbon nanotubes as part of a polymer film. These MWCNTs are positioned at each of the traces and enable smoother adhesion between layers. These responsive heating elements are within the interfaces of the filament at a micro-scale.

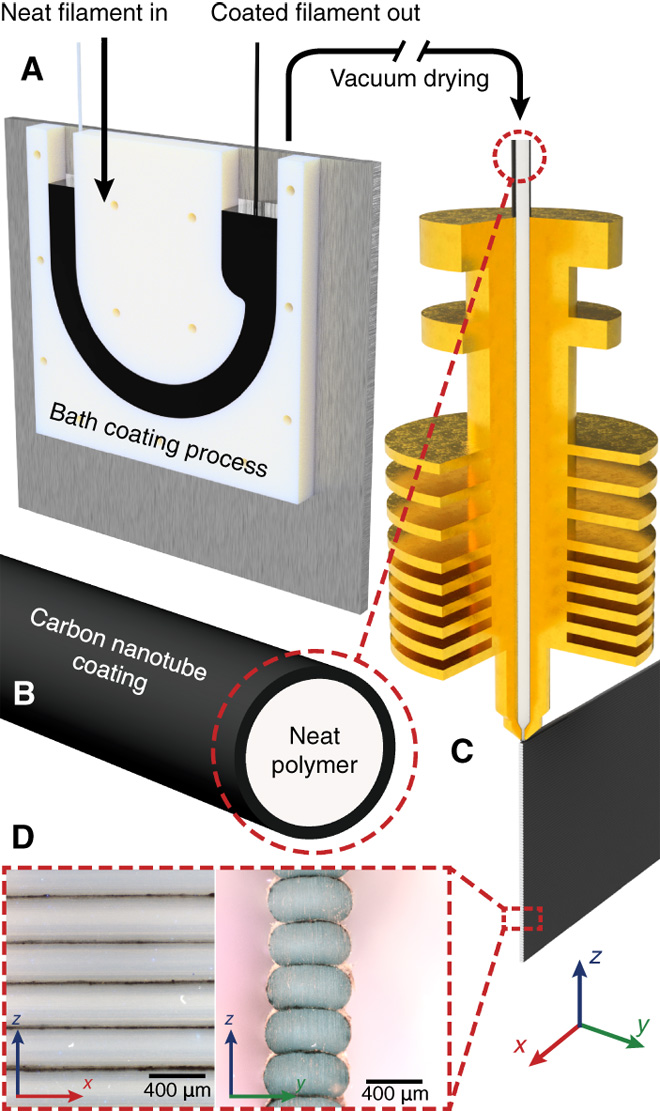

The researchers used a carbon nanotube ink to create the outer layer of MWCNTs that adhere to the PLA. The image below shows the bath coating process. The neat filament enters through one end of the bath and comes out the other side fully coated in a layer of carbon nanotubing. Then, it passes through a vacuum for the drying process.

The entire tech is reliant on the precise coating and microwave responsiveness. As a result, factors like the thickness of the coating and the precise MWCNT count has to be accurate and calibrated to take the post-heating state of the tube into account as it gets thinner.

This method, as it is, does imply a few limitations. For example, currently there is a steep limit to the level of thickness that the coat can achieve before it starts to become counterproductive. Similarly, over stuffing the coating with MWCNTs also produces less than desirable results with flow instability.

All in all, the research is very intriguing. It has wide implications for how we think about filament production. It can also give manufacturers a way of achieving better prints without changing the whole material and instead coating it with conductors. We’ll have to wait and see how it develops as further tests are conducted, but so far it looks encouraging.

The full study is available here.