Engineers at Princeton University are using lasers to address a key issue with 3D printed cement – its susceptibility to fractures. By evaluating the material’s resistance to cracking, the researchers aim to expand the use of additive manufacturing in cement-based structures and develop superior materials through innovative designs and functions.

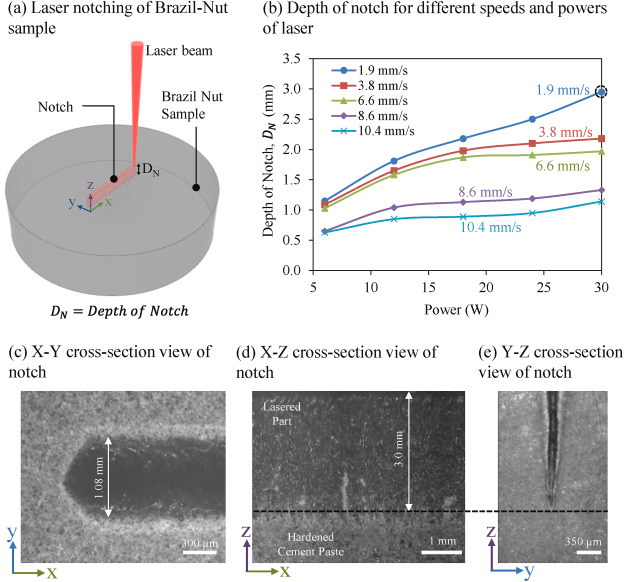

While 3D printing offers efficiency and versatility, 3D printed concrete has shown a tendency to crack, especially in the areas between different layers. This is attributed to non-uniform microstructures resulting from the layering process. To gain a deeper understanding of this cracking phenomenon, the Princeton researchers have introduced a new testing method that employs lasers to create precise grooves in 3D-printed cements. The laser’s power and speed can be controlled to determine the grooves’ depth and shape, enabling more accurate testing compared to conventional methods.

The study, published in the journal Cement and Concrete Composites, highlights the potential for 3D-printed concrete to match or surpass the strength of cast concrete by characterizing its fracturing properties. The ability to comprehensively understand the fracture behavior of 3D-printed cement-based materials is crucial for advancing this technology on a larger scale.

By leveraging additive manufacturing’s design freedom and material architecture, there are opportunities to create stronger and more durable materials. The researchers at Princeton, led by Reza Moini, are dedicated to improving additive manufacturing techniques for cement-based materials, aiming to overcome the structural weaknesses caused by water-rich films formed during extrusion.

Laser Notching

Using lasers instead of physical tools like saws to create notches for testing allows for more precise evaluation of the microstructures and interfaces between layers. This approach enables researchers to assess the material’s resistance to cracking under various conditions, such as tension and shear.

A fracture test less commonly used in concrete materials, known as the Brazil-Nut test, was proposed to facilitate the characterization of fracture toughness of 3D-printed cementitious materials in Mode-I/II in two orthogonal directions. A laser processing of hardened brittle cement paste materials was proposed for the first time to allow for the creation of a sharp V-shaped notch with consistent and controlled depth.

Princeton’s ongoing research focuses on investigating architected materials and fracture characteristics to further enhance the understanding of 3D-printed concrete. The team’s work has gained recognition, with graduate students receiving awards for their contributions at industry conferences.

You can read the full paper, titled “Fracture and transport analysis of heterogeneous 3D-Printed lamellar cementitious materials” over at this link.

Come and let us know your thoughts on our Facebook, Twitter, and LinkedIn pages, and don’t forget to sign up for our weekly additive manufacturing newsletter to get all the latest stories delivered right to your inbox.