Researchers in Singapore have published a paper demonstrating the printing of stretchable conductive fibers, for the fabrication of multifunctional electronic textiles.

Read on to learn more about the research..

Conductive Fibers

A new method of integrating highly stretchable conductive fiber into ready-made garments with designed patterns has been developed by researchers at NTU Singapore, and Southern University of Science and Technology, China.

This method is used for the fabrication and integration of functional fiber into textiles without the need for tearing down the clothing and re-weaving, as is the usual way of making this kind of thing.

The sheath-core fiber consists of a SEBS (styrene–ethylene–butylene–styrene) shell and a Ga-In-Sn alloy liquid metal core, providing high stretchability and flexibility while maintaining high conductivity at large deformation.

This method enables the implementation of sophisticated patterns that are difficult to incorporate into textiles and ready-made garments by traditional methods.

Liquid Core

The increasing demand for flexible electronics that fit well in clothes or fabrics has led to the development of stretchable conductive fibers with properties such as lightweight, high flexibility, and stretchability. However, the challenge of maintaining conductivity while maintaining flexibility under large deformation remains.

Recently, liquid metals, such as Ga–In–Sn alloys, have attracted attention due to their liquidity and high conductivity at room temperature, making them excellent candidates for wearable devices. Liquid metal fibers offer the feasibility of creating elastic electronic devices with high conductivity and continuity through flow under deformation.

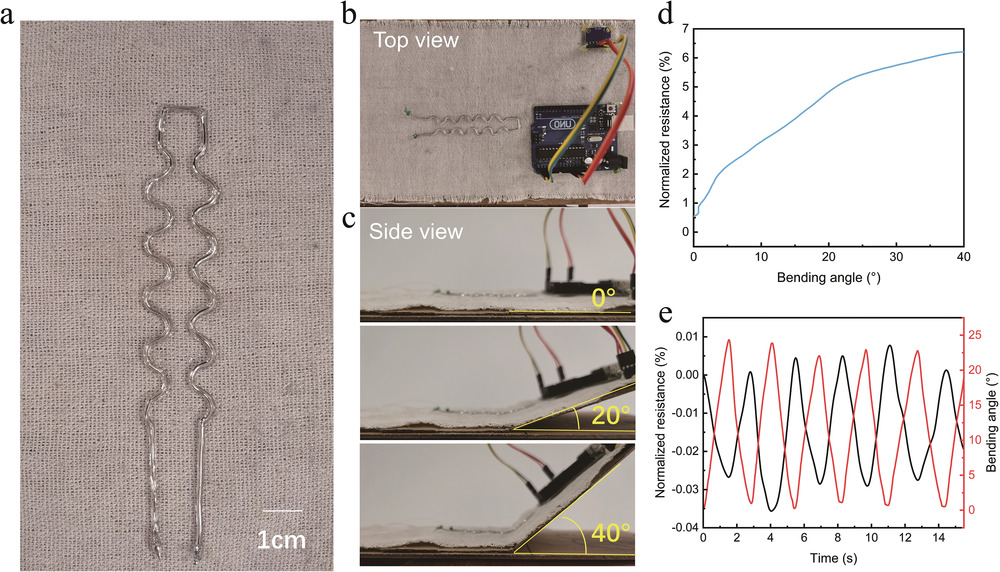

Using these methods, the researchers were able to demonstrate applications for wearable electronics, such as on-clothing strain sensors and touch-sensing networks.

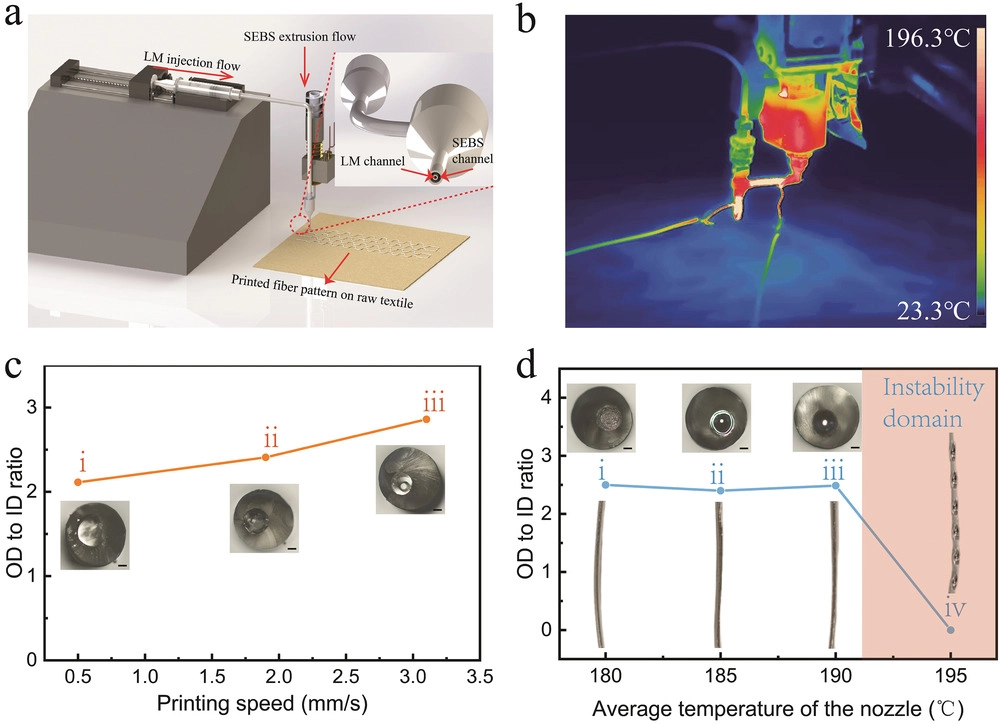

You can see the apparatus used to fabricate these fibers in the image below.

The development of a soft sheath-core fiber was achieved using a modified commercial 3D printer (Anycubic Chiron). Traditional 3D printers are not suitable for printing low-stiffness elastomers such as styrene-ethylene-butylene-styrene (SEBS) due to the requirement for material rigidity to maintain continuous feeding during printing.

To address this, the Bowden extruder was modified into a customized pellet extruder, allowing for direct extrusion from pellets without material rigidity requirements. Additionally, the single-channel nozzle was modified into an assembled coaxial nozzle, enabling a co-flow printing with two-material input, where the inner channel was connected to a syringe pump, and the outer channel was coupled with the customized pellet extruder.

Very Stretchy

The excellent stretchability of the printed fiber was achieved due to the high stretchability of the SEBS shell and the fluidity of the liquid metal core. The fiber was able to withstand up to 500% elongation without breaking down.

The study also investigated the strain-stress relationship of fibers with different inner and outer diameters, and no defects were observed in the microstructure of the fiber even after 1000 stretch cycles.

Conclusion

The fiber has many potential applications, including stretchable electrical current buses, resistive sensing parts, and electromagnetic coupling sections. Demonstrations of various applications, such as bend sensing, wireless energy transfer, and distributed sensing networks, showed the fiber’s unique electrical and mechanical properties.

With the advantages of in situ 3D printing, the sheath-core fiber can potentially serve as a building block for integrating functional devices into fabrics for soft robotics, environment sensing, and healthcare monitoring.

You can access the paper, titled “Multifunctional Electronic Textiles by Direct 3D Printing of Stretchable Conductive Fibers”, over at this link.

Come and let us know your thoughts on our Facebook, Twitter, and LinkedIn pages, and don’t forget to sign up for our weekly additive manufacturing newsletter to get all the latest stories delivered right to your inbox.