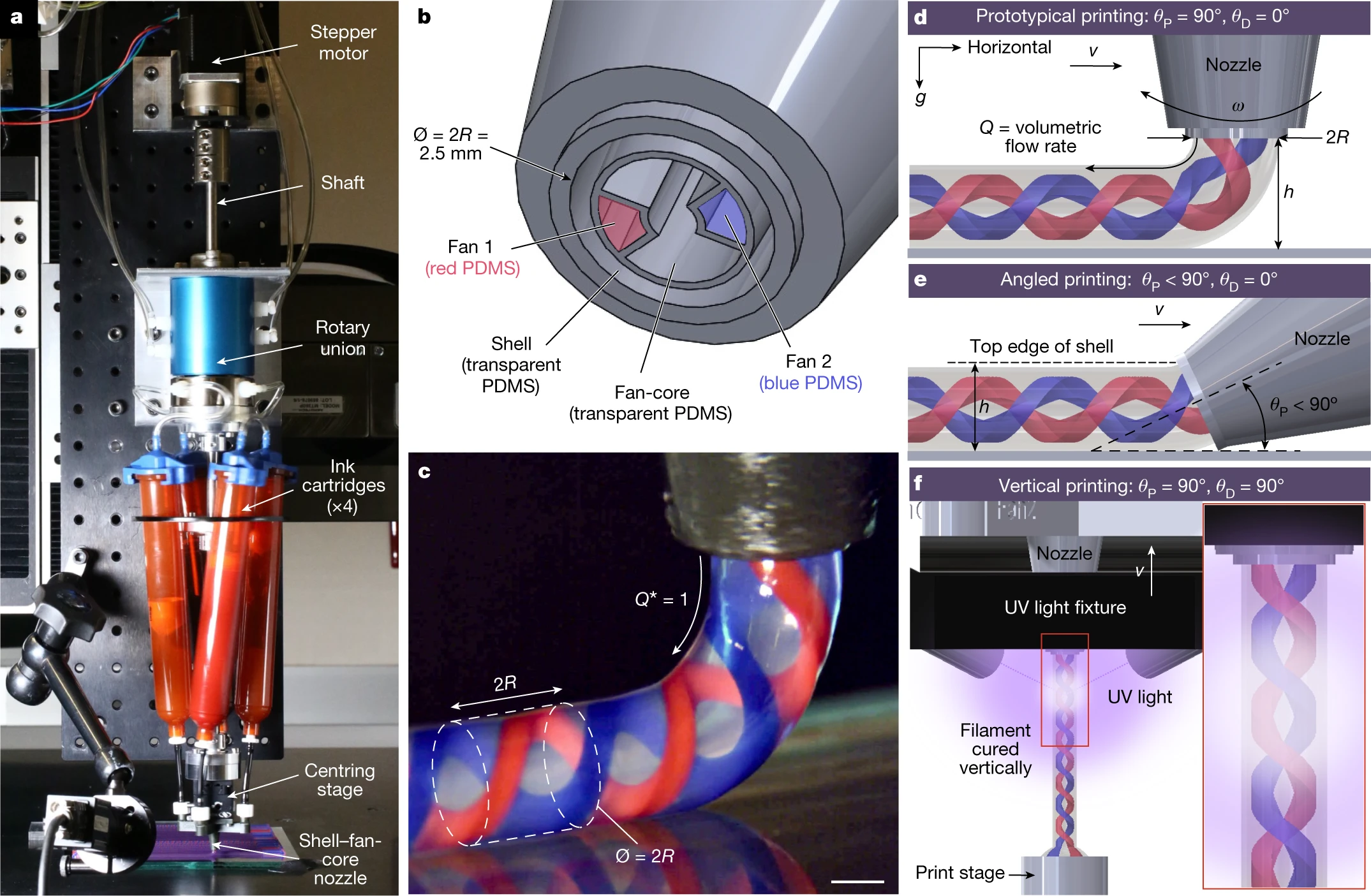

Researchers from Harvard University have published a paper detailing their work in 3D printing helical multi materials from a singular rotating nozzle.

They have named the method RM-3DP, or rotational multi material 3D printing.

The process allows for the simultaneous creation and patterning of multimaterial, helically architected filaments with subvoxel control in 2D and 3D motifs using different materials.

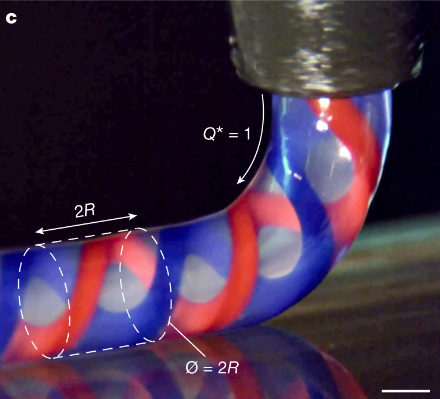

Before we get into the nitty-gritty, let’s take a look at a picture to illustrate the result.

The RM-3DP process works by continuously rotating a multimaterial nozzle with a controlled ratio of angular-to-translational velocity. The resin tanks are mounted above the nozzle, and also rotate with the extrusion head.

This allows for the creation of helical filaments with programmable helix angle, layer thickness, and interfacial area between different materials within a given cylindrical voxel. The cylindrical voxel is defined as by the nozzle diameter multiplied by a length of extruded filament equal to 2x the radius of the nozzle, or 2πR^3 for short. After the extruded helical tracks are laid down, a UV lamp passes over the tracks to cure them.

You can see the whole extrusion and rotating resin tank apparatus in the video below.

The nozzles have a unique shell-fan-core design utilizing fan elements that create an azimuthally heterogeneous structure. They allow for the free rotation of ink reservoirs and the nozzle using a 4-channel rotary union, which directs pressurized air from stationary inlets to rotating outlets.

HDEAs

The researchers have explained that there is more to this process than simply printing colorful tracks. These are not simply different colors within the helix, but they are indeed multi materials, and in one demonstration the team successfully printed conductive and insulating materials from the same nozzle.

The result was a helical dielectric elastomer actuator (HDEA) filament with discrete, individually addressable helical conductive channels embedded within a dielectric elastomer matrix.

A HDEA is a type of electroactive polymer that changes shape when an electric field is applied to it. When voltage is applied, the material contracts or expands, causing the actuator to change shape. This motion can be used to power mechanical devices such as robots and artificial muscles. HDEAs are lightweight, low-power, and highly compliant, making them suitable for multiple uses including robotics, biomedical devices, and smart materials.

Previous methods of fabricating HDEAs involve helical cutting of a dielectric elastomer tube and deposition of compliant electrodes on the helix faces.

However, using RM-3DP, HDEAs can be rapidly printed in a single step by co-extruding two viscoelastic inks from the shell-fan-core nozzle to simultaneously form both dielectric and conductive components in a helical geometry. The conductive parts are printed with inks containing carbon.

You can see the extrusion and curing process, along with the finished HDEA functioning in the video below.

Springy Filaments

In addition to the HDEAs, the researchers demonstrated the fabrication of springy filaments and matrixes. The result was a structural composite composed of stiff and soft sub voxelated elements. The springy filaments were fabricated by co-extruding two viscoelastic inks from the fan-core nozzle to embed stiff acrylic springs (blue fan features) within a soft acrylic matrix (transparent fan-core feature).

The researchers demonstrated that the tensile mechanical behavior of the springy filaments could be tuned by varying ω* (the dimensionless rotation rate). It was shown that as ω* was increased from 0 to 5, the tensile strain at failure showed an approximately 30 to 40 fold increase.

You can read the full paper, and check out the other interesting supplemental videos published on Nature, over at this link.