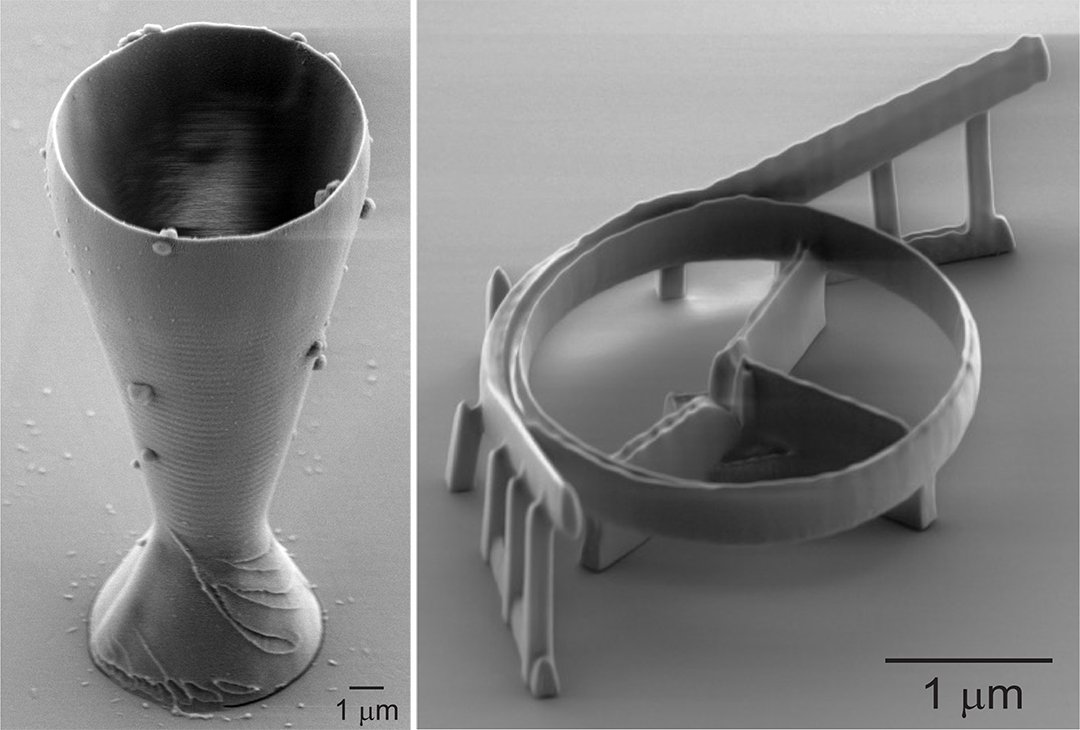

Researchers at the KTH Royal Institute of Technology in Stockholm have achieved a significant breakthrough in 3D printing by creating the world’s smallest wineglass using a simplified technique for printing silica glass structures.

No, it’s not really for ants. That’s just a meme. Read on to know more about why the researchers would do such a thing.

Tech Demonstrator

The diminutive drinking vessel has served as a demonstration of the researchers’ printing technique, which utilized the local crosslinking of hydrogen silsesquioxane to silica glass using nonlinear absorption of sub-picosecond laser pulses. This method of 3D printing of solid silica glass with sub-micrometer resolution demonstrated the fabrication of silica glass without the need of a sintering step, and has potential for various applications, including telecommunications and robotics.

Traditionally, 3D printing silica glass components required thermal treatment, which added complexity to the process. However, the new technique developed by KTH overcomes this challenge. The simplified method significantly reduces the energy required to print silica glass and eliminates the need for thermal treatment. Additionally, readily available commercial materials can be used, making it more accessible for widespread use.

Applications of Mini Glass Printing

The implications of this breakthrough are vast. Customized lenses for medical machinery, micro-robots capable of navigating extreme environments, and filters and couplers for fiber optic networks are just a few examples of potential applications. The researchers successfully printed a fiber optic filter directly onto the tip of an optical fiber as thin as a strand of human hair, highlighting the versatility and practicality of the technique.

The ability to 3D print glass structures without thermal treatment opens up new possibilities for the integration of 3D printing methods in practical scenarios. The method holds promise for optimizing applications in different fields, and its energy efficiency and compatibility with commercial materials make it a valuable advancement in the realm of 3D glass printing.

With further refinement, this breakthrough has the potential to revolutionize the production of tiny glass components for a wide range of industries – including ant wine bars (if they exist).

You can read the research paper, titled “Three-dimensional printing of silica glass with sub-micrometer resolution” in Nature Communications, at this link.

Come and let us know your thoughts on our Facebook, Twitter, and LinkedIn pages, and don’t forget to sign up for our weekly additive manufacturing newsletter to get all the latest stories delivered right to your inbox.