A team led by Chris Williams, the L.S. Randolph Professor in Mechanical Engineering at Virginia Tech, has received a $1.5 million grant from the REMADE Institute to develop a novel 3D printing process for tire retreading in the commercial vehicle industry.

The project aims to improve the efficiency of the retreading process and reduce waste and emissions. Currently, when commercial vehicle tires wear out, they undergo retreading, which involves buffing the tire’s surface and applying a new layer of tread. While retreading reduces waste compared to replacing tires entirely, there are still inefficiencies in the system, resulting in excess material waste and potential drops in fuel efficiency.

Williams’s team plans to integrate advances in polymer science, 3D scanning, 3D printing, and industrial robotics to enhance the retreading process. The goal is to reduce waste by approximately 90 metric kilotons of tire waste and 800 metric kilotons of CO2 emissions annually across the retreading industry.

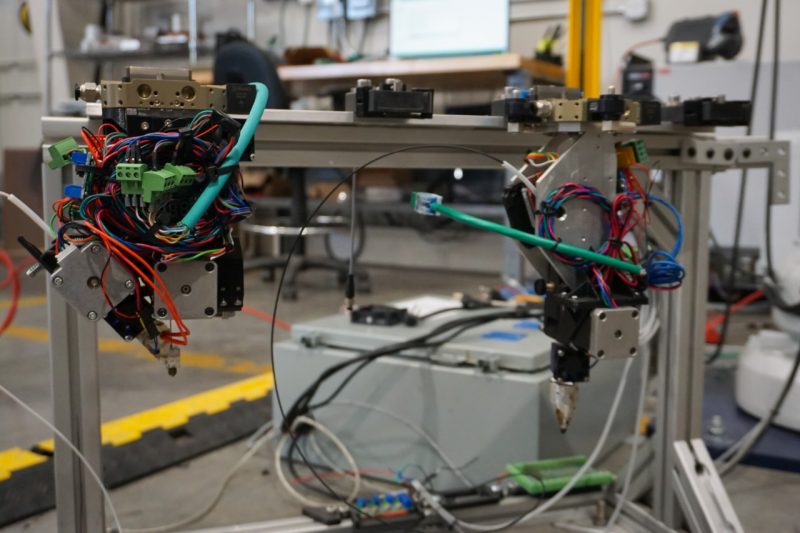

The team will use 3D scanning technologies and new materials resistant to the demands of commercial vehicle tires. Industrial robots will selectively print these materials onto specific areas of the used tires.

The project aligns with the REMADE Institute’s mission to accelerate the nation’s transition to a circular economy. By maximizing the reuse and recycling of materials, a circular economy aims to improve efficiency and reduce waste. The anticipated results of this project will contribute to the United States’ energy conservation and emissions reduction targets.

Collaborators from Virginia Tech, Arizona State University, and Michelin will contribute their expertise in polymer science, high-performance elastomer synthesis, tire design and performance characterization, and industrial sustainability goals. The project will require a transdisciplinary approach, considering materials, additive manufacturing processes, and tire performance.

Come and let us know your thoughts on our Facebook, Twitter, and LinkedIn pages, and don’t forget to sign up for our weekly additive manufacturing newsletter to get all the latest stories delivered right to your inbox.