Microfluidics involves controlling fluids at micron scales, enabling diverse applications like cancer screening and drug testing. Traditionally, developing microfluidic devices is complex and expensive, requiring advanced equipment and cleanroom facilities. However, 3D printing offers a cost-effective alternative, allowing rapid iterations and reduced infrastructure costs.

Stereolithography (SLA) is a favored 3D printing method for its high precision. Nonetheless, it faces challenges like light penetration affecting print quality, particularly in small or multilayer devices. Solutions like printer modifications or custom resins are not widely accessible, highlighting the need for more efficient design tools.

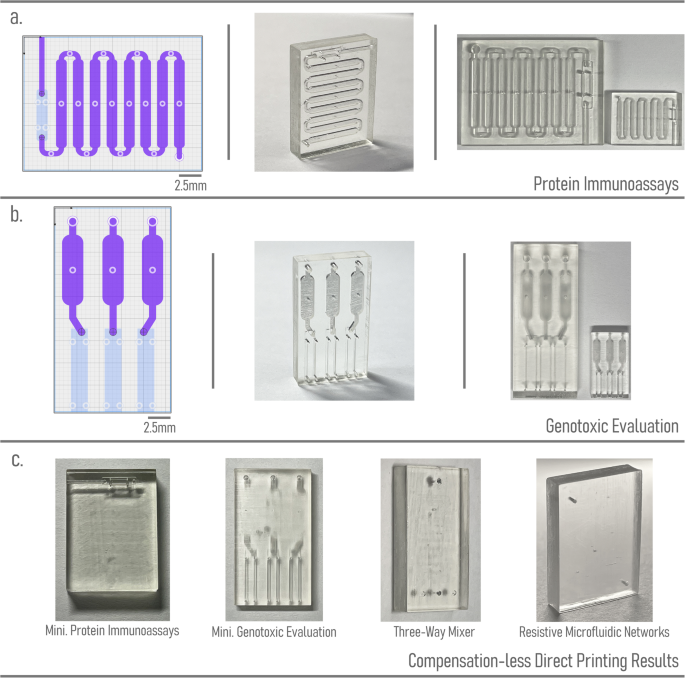

Flui3d is an open-source interactive platform tailored for designing 3D printed microfluidic devices. It dynamically optimizes designs for manufacturing, compensating for light penetration issues by adjusting design dimensions during output. This enables effective fabrication without specialized printers or resins.

Flui3d’s user-friendly interface features a parametric microfluidic component library, facilitating easy design through simple clicks. It supports both planar and multilayer designs, generating STL files for 3D printing or SVG files for other fabrication methods. Designs are exportable in JSON format, promoting community sharing and reuse.

The platform streamlines the design process, requiring no prior 3D modeling experience. Users can place modules in a 2D interface, with Flui3d automatically generating the corresponding 3D design. Comparative studies demonstrate that Flui3d efficiently produces high-quality microfluidic devices using consumer-grade 3D printers.

Flui3d enhances accessibility to low-cost, 3D-printed microfluidics, making advanced microfluidic design feasible for researchers and practitioners across various fields.

You can read more about the research that developed Flui3D over at this link.