Engineers from the University of Colorado and Sandia National Laboratories have developed advanced padding designs that promise superior impact absorption. Published in the Advanced Materials Technologies journal, the research introduces intricate geometrical alterations to conventional foams, enhancing their ability to withstand significant forces.

The team’s approach focuses on redesigning the internal structure of cushioning materials, enabling controlled buckling under pressure. This innovation not only outperforms current technologies but also offers versatility in absorbing various types of impacts, making it ideal for applications ranging from sports gear to packaging materials.

“Impact mitigation is something that’s important everywhere,” said Robert MacCurdy, assistant professor of mechanical engineering at CU Boulder.

“It’s in highway crash barriers, knee pads and elbow pads, and in packaging equipment.”

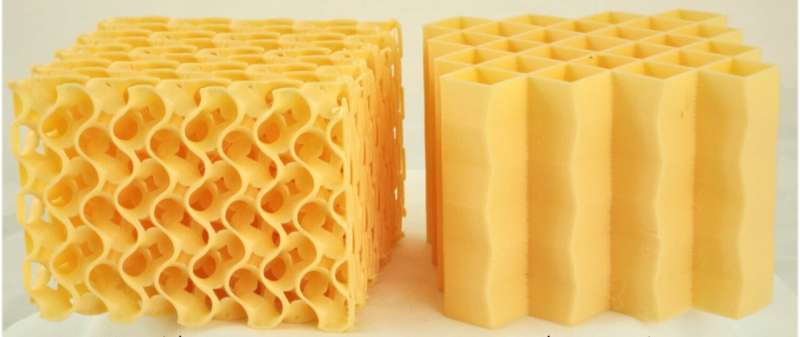

Utilizing custom algorithms, the engineers crafted honeycomb-like structures with strategically placed kinks to guide controlled collapse during impact, ensuring consistent force absorption across different compression levels. Laboratory tests demonstrated a remarkable increase in energy absorption compared to standard foams, highlighting the potential for these designs to revolutionize impact protection.

Further advancements are underway, with researchers exploring diverse materials and refining the structural integrity of their designs. With these developments, the future holds the promise of safer environments, where advanced padding technologies mitigate risks and safeguard individuals and objects alike.

You can read the full research paper, titled “Tunable Metamaterials for Impact Mitigation” at this link.

Come and let us know your thoughts on our Facebook, X, and LinkedIn pages, and don’t forget to sign up for our weekly additive manufacturing newsletter to get all the latest stories delivered right to your inbox.