Researchers at McGill University and Drexel University have developed a manufacturing technique that uses female mosquito proboscides as high-resolution 3D printing nozzles. The biological feeding tubes enable printed line widths as fine as 20 microns, roughly twice as precise as commercially available printing nozzles. The team named the process “3D necroprinting,” where non-living biological microstructures serve as manufacturing tools.

The mosquito proboscis, about half the width of a human hair, was identified as the optimal candidate for creating ultra-fine nozzles. Researchers harvest the feeding tubes from euthanized mosquitoes sourced from laboratory colonies at Drexel University, then attach them to standard plastic dispenser tips using resin. The biological nozzles are integrated into custom 3D printing setups for use in applications such as tissue engineering scaffolds and microscopic object transfer.

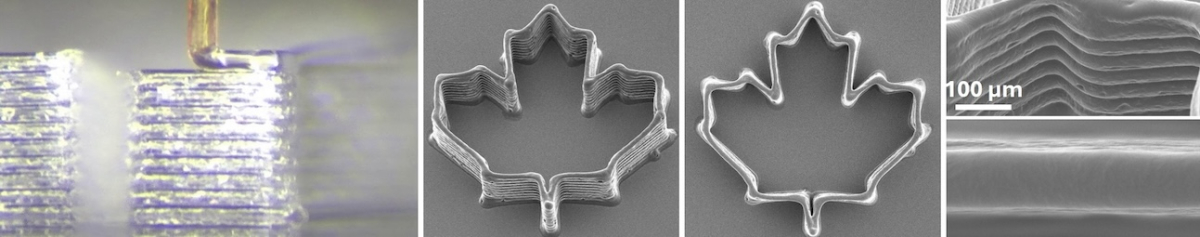

“High-resolution 3D printing and microdispensing rely on ultrafine nozzles, typically made from specialized metal or glass,” said study co-author Jianyu Li, Associate Professor and Canada Research Chair in Tissue Repair and Regeneration at McGill. “These nozzles are expensive, difficult to manufacture and generate environmental waste and health concerns.” The research team has successfully printed complex structures including honeycombs, maple leaves, and bioscaffolds containing cancer cells and red blood cells.

The mosquito nozzles demonstrate durability and reusability when pressures remain within safe limits. “We found the mosquito proboscis can withstand repeated printing cycles as long as the pressures stay within safe limits. With proper handling and cleaning, a nozzle can be reused many times,” said co-author Changhong Cao. The study, led by McGill graduate student Justin Puma, was published in Science Advances and received funding from multiple Canadian research organizations.

Source: mcgill.ca