Additive manufacturing technologies have enabled the production of highly customized and complex parts, including mechanically efficient lattices with optimized strength-to-weight ratios. However, the layer-by-layer construction process has limited the fabrication of regular lattices, such as octet cells, due to the introduction of additional interfaces and support requirements.

A team of researchers from the University of Padova in Italy has come up with a new method of fabricating more complicated lattices using a robotic arm combined with a Direct Ink Writing system.

Read on to learn more about it.

Octet Cells

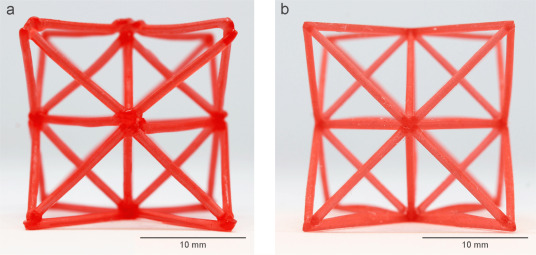

As you can see in the image of the printed octet cells below, this type of lattice would have some issue being printed with any type of 3D printer system requiring support materials, due to the horizontal beams of the lattices. However, as you can also see, these lattices turned out fine, because they were printed with the Padova team’s process.

To obtain these results, a hybrid extrusion-photopolymerization process was coupled with a 6-axis robotic arm, allowing for the creation of layer-less lattices. A custom graphical user interface and control over the printing head orientation enabled precise fabrication, while a highly reactive resin loaded with silica particles was used to tailor the ink’s rheological properties.

The Process

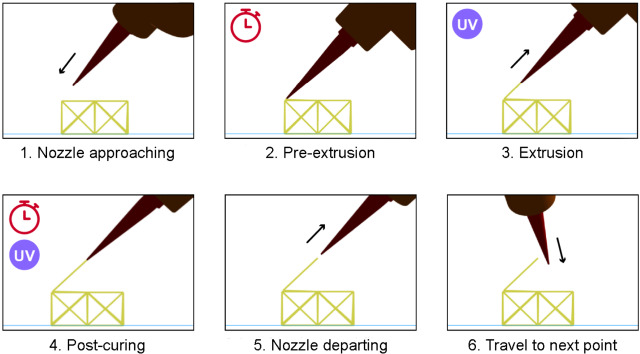

The process of creating 3D printed trusses using a robotic arm involves several steps. The first step is to move the extruder to the starting point of the truss while keeping its axis aligned with the direction of the truss. Once in position, the extruder pre-extrudes ink to ensure adhesion to the platform or previously printed part. The filament is then extruded while moving at a certain printing speed with the UV light on. After the filament is printed, it is exposed to additional UV light for a set time period to further cure it. The post-curing time is found to be linearly proportional to the printing speed. Once cured, the extruder departs from the filament and moves to either continue constructing the next truss or to the nozzle cleaning stage.

Thanks to the custom-developed GUI, it is possible to tilt the printing head and orient it along the truss axes, consequently avoiding the partial hindrance of the extruded filament by the nozzle and allowing for precise shape retention along the defined printing paths.

By following this process, the 3D printed trusses were able to maintain their shape and structure without additional support.

The resulting components exhibited excellent mechanical properties and closely resembled their digital models, surpassing the performance of traditionally additively manufactured octets.

Conclusion

The UV-DIW technique coupled with a 6-axis robotic arm was effectively utilized to fabricate regular octet lattice structures with excellent strength and energy absorption capabilities.

While a higher printing resolution could be achieved with DLP, the hybrid technique provided an advantage by eliminating interlayer interfaces and increasing the overall mechanical response of the structure. However, according to the research paper, accuracy was found to be somewhat compromised, and adjustments to the setup could have been made to improve this.

Future work will focus on using different materials to further advance the capabilities of the hybrid setup, potentially enabling the combination of ceramic materials with the mechanical properties of complex, stretch-dominated structures printed using the robot-assisted UV-DIW setup.

Overall, this approach to non-planar printing with photopolymers has, according to the researchers, the potential to unlock new possibilities in lattice design.

You can read the full paper, titled “Development of robot assisted hybrid additive manufacturing technology for the freeform fabrication of lattice structures” in the Additive Manufacturing journal, over at this link.

Come and let us know your thoughts on our Facebook, Twitter, and LinkedIn pages, and don’t forget to sign up for our weekly additive manufacturing newsletter to get all the latest stories delivered right to your inbox.