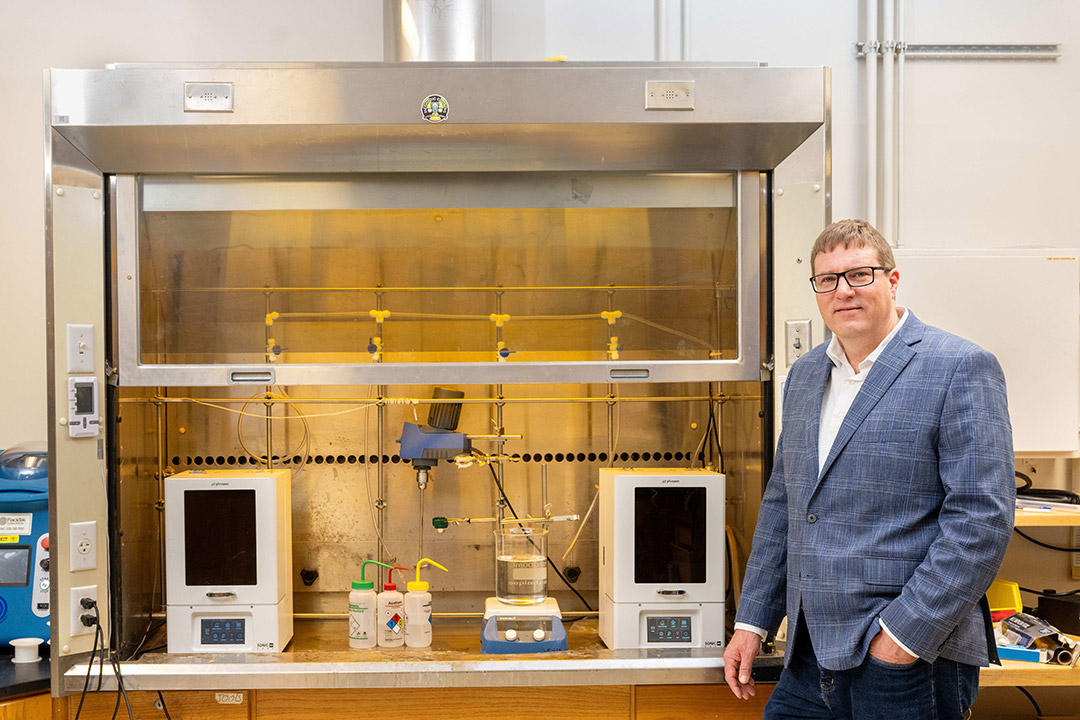

Researchers at Rochester Institute of Technology have developed self-healing materials designed to improve the durability of 3D-printed products. Christopher Lewis, an associate professor in RIT’s College of Engineering Technology, led the research team in creating stimuli-responsive photopolymer solutions that can repair themselves when damaged.

The team combined thermoplastic agents with ultraviolet-curable resins to create stronger 3D-printed materials. This approach addresses a common problem in 3D printing where objects can crack over time, particularly in load-bearing applications, due to the inherently brittle nature of many printing materials.

“When you break a bone, or cut yourself, we take it for granted that there is a self-repairing mechanism that allows for bones or skin to rejuvenate themselves, at least to some extent,” said Lewis. “We also learn that it is not true for synthetic materials or man-made objects. And our work in self-healing materials is a futuristics look at how we can develop systems that mimic those natural material properties.”

The research utilizes a process called polymerization induced phase separation (PIPS), where thermosetting and thermoplastic materials separate during curing. This allows light to pass through the system while enabling the self-healing properties. Lewis received funding from the U.S. Department of Defense and partnered with RIT’s AMPrint Center to test the materials.

The team has published their findings in several journals including ACS Applied Polymer Materials and Polymer. The researchers believe the technology could benefit industries requiring high-precision equipment, including aerospace, automotive, and biomedical applications where reliable material strength is critical.

Source: rit.edu