Researchers at RMIT University have developed a new titanium alloy that costs 29% less to produce than standard titanium used in 3D printing. The team replaced vanadium, an increasingly expensive component, with cheaper alternative materials while maintaining improved strength and performance compared to the widely-used Ti-6Al-4V alloy.

The research, published in Nature Communications, presents a framework for predicting the printed grain structure of metallic alloys in additive manufacturing. RMIT has filed a provisional patent on the approach and is exploring commercial opportunities in the aerospace and medical device industries.

PhD candidate Ryan Brooke, the study’s lead author, explained the significance of developing new alloys for 3D printing. “3D printing allows faster, less wasteful and more tailorable production yet we’re still relying on legacy alloys like Ti-6Al-4V that doesn’t allow full capitalisation of this potential. It’s like we’ve created an aeroplane and are still just driving it around the streets,” he said.

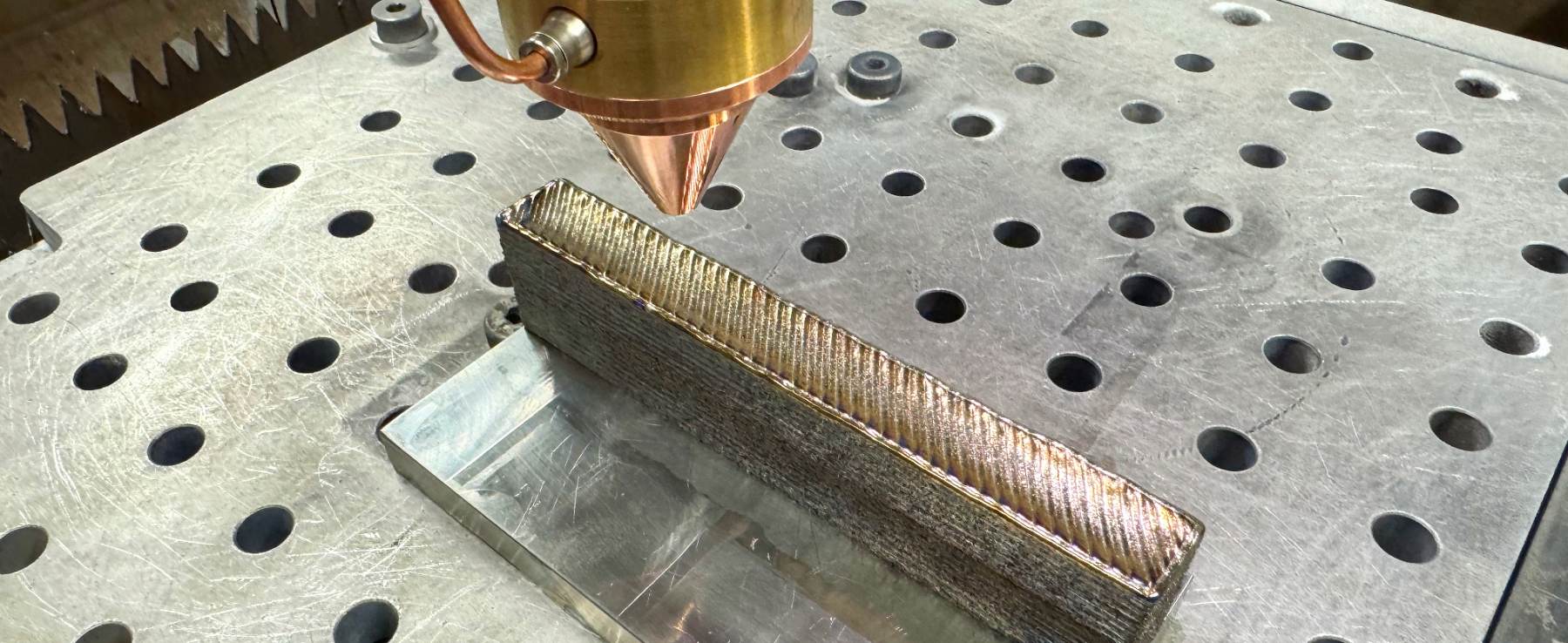

The new alloy addresses two key challenges in 3D printing by reducing costs and avoiding problematic column-shaped microstructures that can lead to uneven mechanical properties. Brooke, who recently accepted a Research Translation Fellowship at RMIT, conducted market validation through CSIRO’s ON Prime program with industry representatives from aerospace, automotive, and medical technology sectors.

Professor Mark Easton, the study’s corresponding author, said RMIT’s Centre for Additive Manufacturing is seeking partnerships to advance the technology. The samples were produced and tested at RMIT’s Advanced Manufacturing Precinct, with the research team now looking for collaborators across the supply chain to support further development.

Source: rmit.edu.au