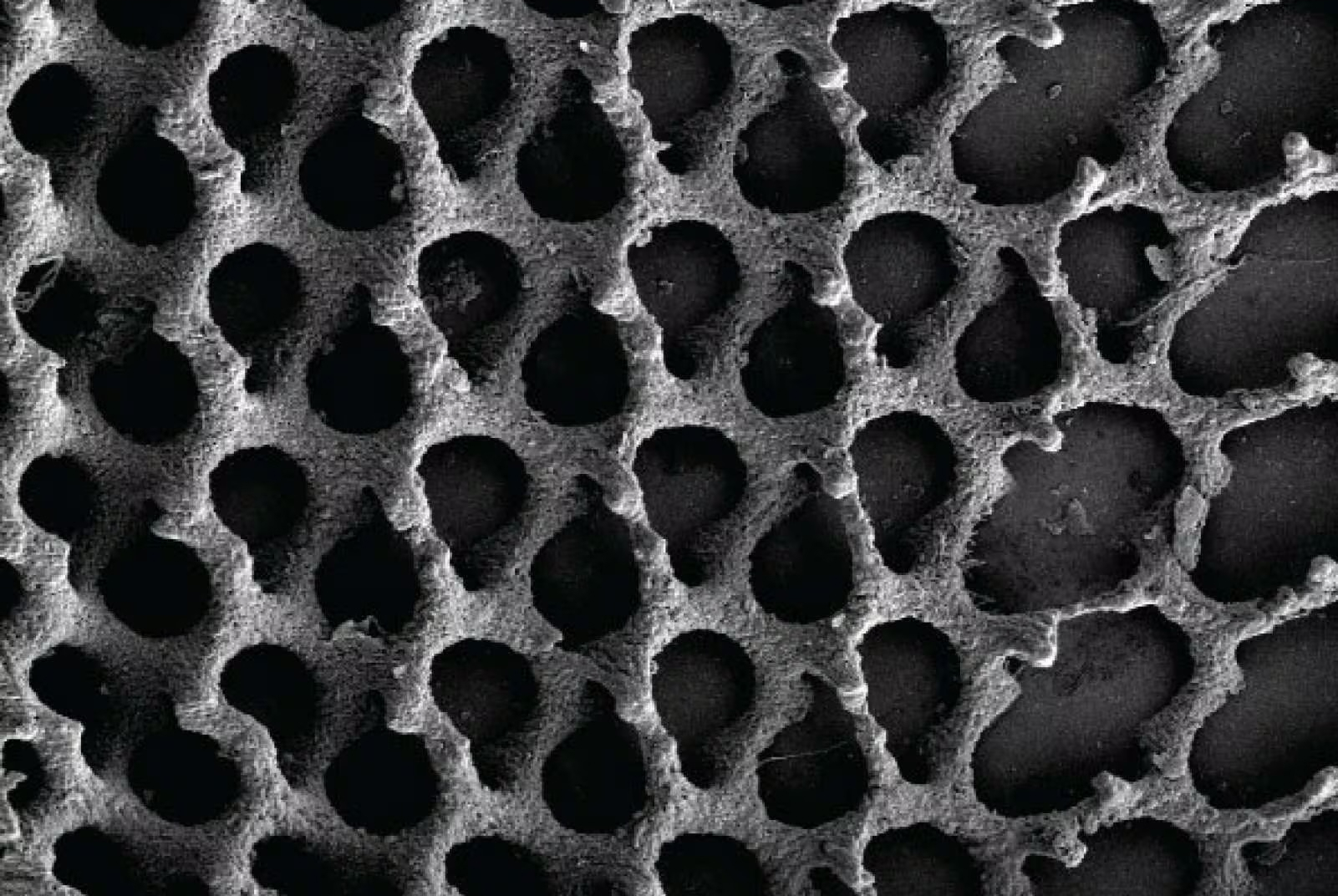

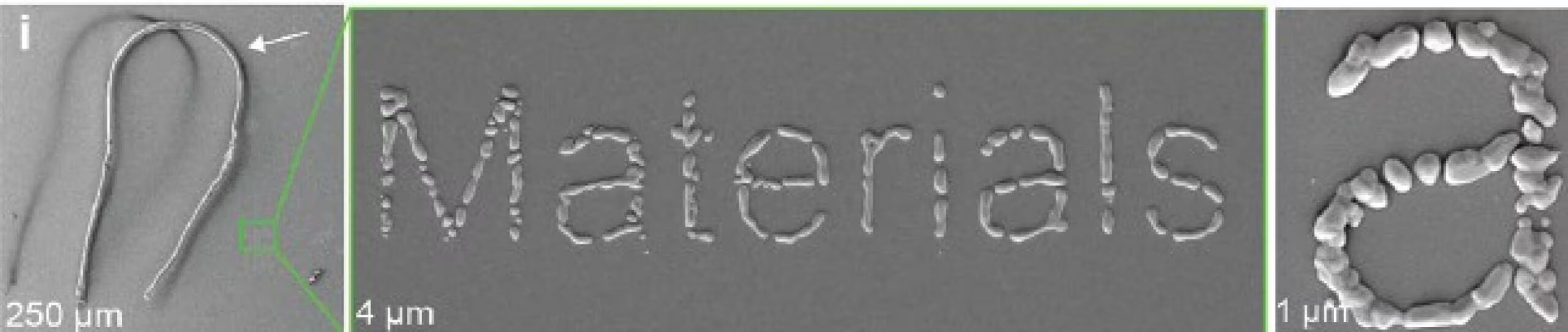

Researchers from the University of Sydney have developed a new 3D printing technique that can recreate synthetic bone at the nanoscale level. The method allows for precise control of grain size and porosity during printing, mimicking the complex architecture of natural bone with 300 nanometer resolution. This advance could potentially improve bone graft surgeries in the future by creating substitutes that more closely resemble natural bone structure.

The technology uses specialized inks made from biocompatible materials like calcium phosphate that resemble the mineral composition of natural bone. According to the research team, the printing technique is one thousand times stronger than existing methods. The development was co-led by Professor Hala Zreiqat from the University of Sydney and Associate Professor Iman Roohani, now at the University of Technology Sydney.

“This reduces the risk of long-term complications and future surgeries and offers a more natural restoration of bone defects,” said Professor Zreiqat, whose team specializes in creating bio-ceramic materials. The research addresses a significant medical need, as Australian statistics show there were over 146,000 joint replacement surgeries in 2023 alone.

The research team overcame technical challenges by using prenucleation clusters, which are naturally found in bone and guide the mineralization process. By incorporating these clusters into a transparent calcium phosphate resin, they were able to mimic micro and nanoscale features of natural bone. The findings were published in Advanced Materials.

Unlike traditional metal implants that provide structural support but don’t participate in healing, these bioceramic materials aim to gradually integrate with the body and encourage new bone formation. The researchers are now working on enhancing the scalability of their printed structures to move the technology closer to clinical applications.

Source: sydney.edu.au