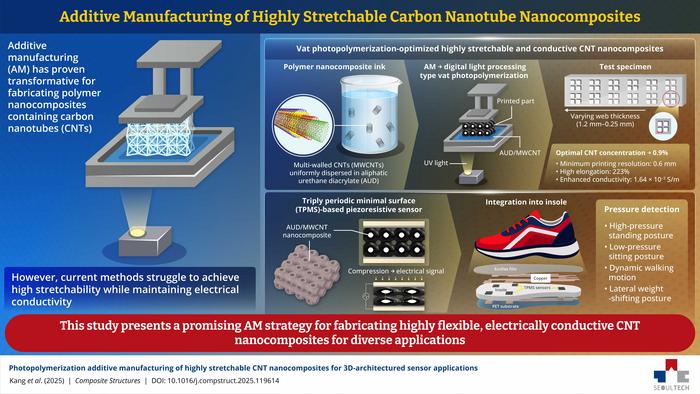

Researchers at Seoul National University of Science and Technology have developed a method to 3D print highly stretchable and electrically conductive materials using carbon nanotubes (CNTs) and polymer composites. The team, led by Professor Keun Park and Associate Professor Soonjae Pyo, used vat photopolymerization (VPP) 3D printing to create nanocomposites that can stretch up to 223% of their original length while maintaining electrical conductivity of 1.64 × 10^−3 S/m.

The researchers addressed long-standing challenges in CNT dispersion by using ultrasonic agitation to mix multi-walled carbon nanotubes within an aliphatic urethane diacrylate photopolymer matrix. They tested concentrations ranging from 0.1 to 0.9 weight percent MWCNTs and found that 0.9 weight percent provided the optimal balance of conductivity and mechanical properties. The process achieved a print resolution of 0.6 mm while preserving the photopolymerization efficiency needed for VPP printing.

The team demonstrated practical applications by creating complex lattice structures that function as piezoresistive sensors capable of detecting mechanical deformation. These sensors were integrated into flexible insoles that can monitor pressure distribution from a user’s foot in real time. The research shows potential for applications in wearable health monitoring systems and soft robotics.

The study addresses the growing demand for flexible electronic components in wearable devices. The VPP-based manufacturing process offers a scalable approach to producing these advanced materials, which could impact industries including healthcare, consumer electronics, and athletics. The research was published with DOI: 10.1016/j.compstruct.2025.119614.

Source: scienmag.com