In the world of oil and gas, it is not always convenient to switch off pipe networks to seal up a potential leak. Sometimes, you just have to slap a metaphorical Band-Aid over it, and await a more permanent solution.

In the world of oil & gas pipe systems, that Band-Aid comes in the form of a repair clamp.

Pre-Engineered Leak Repair

Petrochemical giant Shell has managed to 3D print and install one of these repair claps on one of their sites. The proof of concept was manufactured using Wire Arc Additive Manufacturing (WAAM) technique.

The demo was printed and installed by Shell in collaboration with TEAM, Inc. and Vallourec. The goal of the project was to devise a suitable technical specification, build the part according to it, and then perform tests according to a newly devised inspection plan.

Pipes are prone to defects in the form of cracks, and also via the thinning of the interior walls, which can occur when pressurized fluids erode or corrode the pipe interiors. The clamps are designed for quick installation, and are intended to reduce the amount of disruption to the system in question.

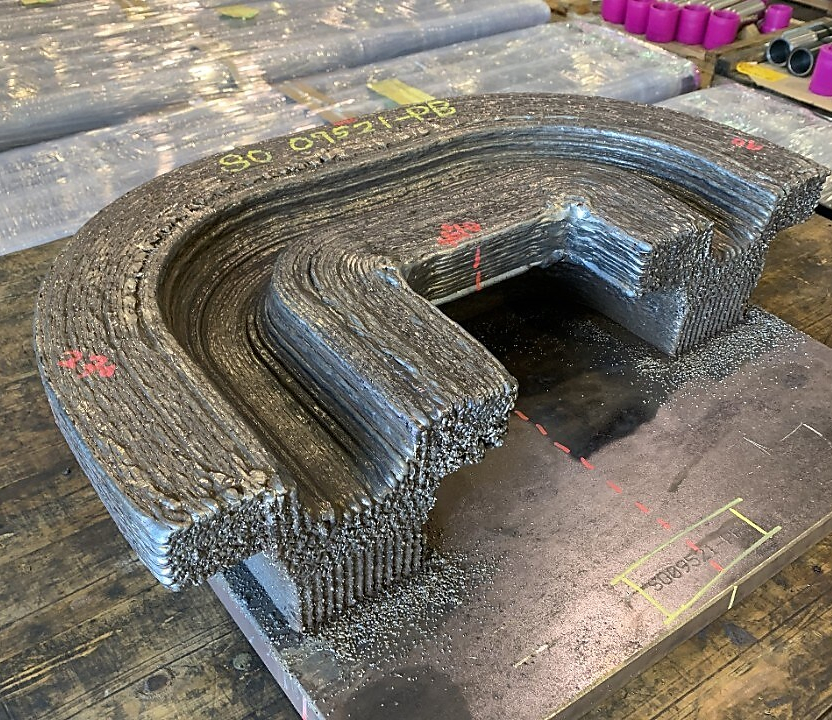

Typically such clamps are made with cast or forged components (as shown above), and consist of multiple parts in an assembly. To manufacture the traditional clamps can take weeks to fabricate and deliver.

The 3D printed versions, which consist of fewer parts, can be manufactured in just 3-5 days.

Now take a look at the WAAM printed clamp in the picture below.

The reduction in size and complexity is apparent.

As mentioned, the clamp solution is more of a Band-Aid…a quick fix to reduce system downtime, and to keep the profits flowing. Sudden leaks in the system also pose an environmental hazard, and so a quick fix is often exactly what the doctor ordered – at least until there is a more opportune moment to shut everything down while a proper fix is delivered.

The printed clamp was subjected to a burst test, and was shown to exceed the design pressure fivefold (142.4 bar). This level of safety factor proved to Shell that it was suitable for installation in the field.

While the clamp can be produced in mere days at production level, these clamps took longer than usual due to requirements for testing prototype parts for critical application. More time was dedicated to the guaranteed success of the part in this case, rather than focusing on design optimization.

Next Steps

Now that the proof of concept has proved viable, the next steps are to improve overall quality and consistency of the part. In addition, reducing the lead time of production level parts is a priority.

Much of the future quality-focused innovation will involve data creation and management. For example, a database will be created containing the inspection and qualification data to reflect the variance in the AM parts, which will assist with the non-destructive evaluation of critical items.

There will be much focus on the qualification requirements, which will allow more complex parts manufactured with WAAM to be quickly assessed based on historical use and on simpler parts made with WAAM.

The demo marks the first time that such a repair clamp has been produced with WAAM.