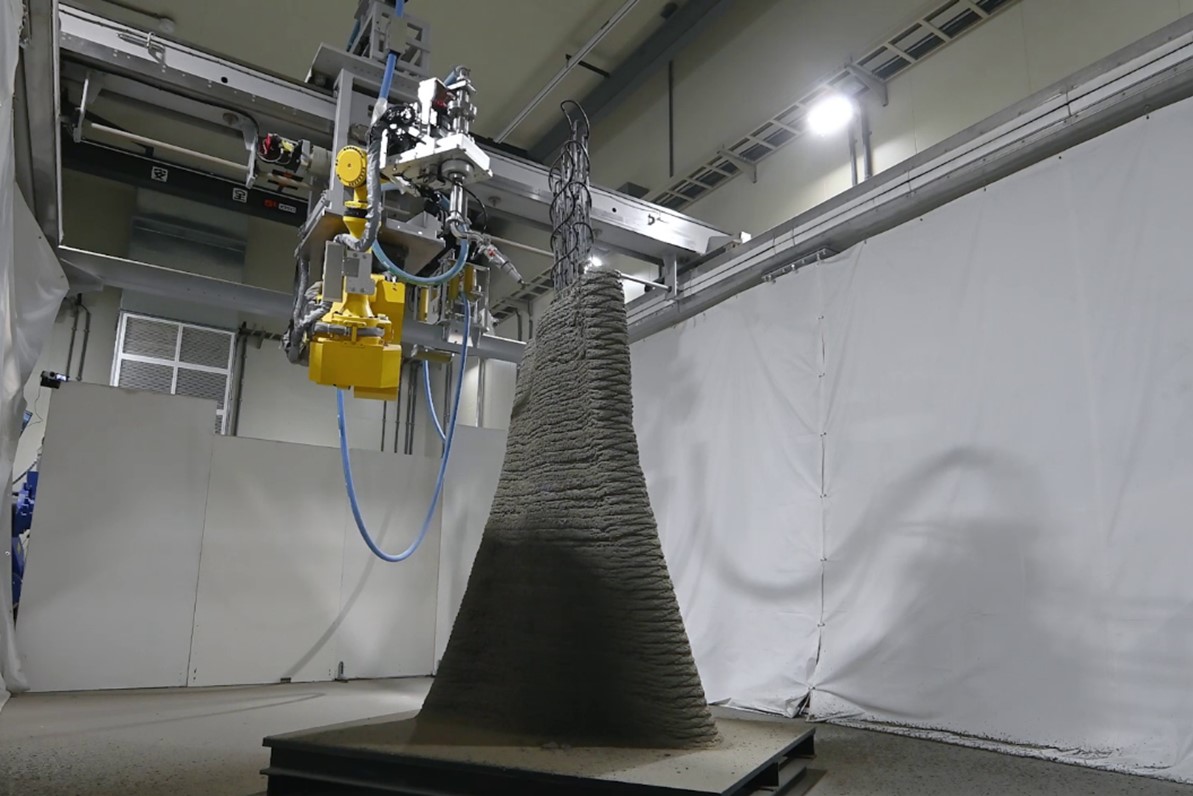

Shimizu Corporation has developed a spray-based 3D concrete printing system designed to construct large, curved reinforced components. The system combines a nine-degree-of-freedom gantry robot with a material spray simulator that can verify sprayed-material behavior before actual printing. The material spray simulator was developed in collaboration with Carnegie Mellon University’s Computational Engineering and Robotics Lab.

The system addresses limitations of conventional material extrusion 3D printing methods, which deposit cementitious materials layer by layer but struggle to integrate rebars into printed layers. Spray-based printing allows for better integration of reinforced structural components by spraying cementitious materials to form structures. However, this method has historically faced challenges with printer motion control and fabrication accuracy.

The new system uses a material spray simulator to determine optimal printing parameters, including nozzle paths, spray distance, angle, speed, and material discharge volume. The gantry robot features a seven-degree-of-freedom arm suspended from a two-axis XY motion mechanism on a portal-type frame. The printable area measures 6 meters in depth, 4 meters in width, and 3 meters in height.

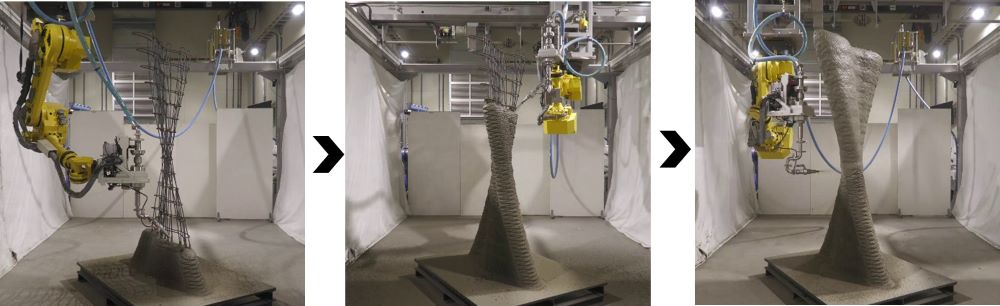

In demonstration tests, the system fabricated a twisted curved wall measuring 2.5 meters in height in four hours. The wall featured both lower and upper layers projecting outward from the center. Shimizu Corporation plans to continue developing 3D printing technologies for construction applications, with a goal of fully automating concrete construction processes.

The development comes as Japan’s construction industry faces workforce challenges due to an aging population and declining birthrate. The company expects that implementing 3D printing of structural components at construction sites will reduce labor requirements and increase design flexibility for structures.

Source: shimz.co.jp