Canada-based aerospace company Delson Aeronautics has won engineering support to assist with the development of their new super quiet drone propellers, which are said to be 50% quieter than commercially available alternatives currently on the market.

The contest, hosted on engineering community website Wevolver.com and sponsored by Mitsubishi Chemical Advanced Materials (MCAM), asked members of the community to design something engineer-y using the KyronMAX range of filled engineering plastics.

Ultimately, the first prize was awarded to Delson Aeronautics who have used the MCAM KyronMAX plastics in combination with a 3D printed injection mold system (SPRINT) to bring their propeller design to realization.

Injection Molding

Typically, commercial drone blades are injection molded from thermoplastics, or else formed in carbon fiber. The key variables designers need to consider when designing drone propellers are the specific strength and the specific stiffness of the material- no point having a strong blade if it will just bend as soon as it takes the weight of the drone.

And conversely, there’s no point having a stiff blade that just snaps under load. Strength, stiffness and lightweight are needed, hence the specific strength and specific stiffness, which both consider the mass of the material in question.

The KyronMAX materials come in a range of high strength polymers and with a variety of chopped fiber fillers, ensuring that parts made with these materials retain the polymer strength plus the added stiffness of the fiber.

Usually, injection molding of these materials would be prohibitively expensive for a small company just starting out, with mold design potentially running into tens of thousands of dollars for a small part (millions of dollars for something as big as a car dashboard).

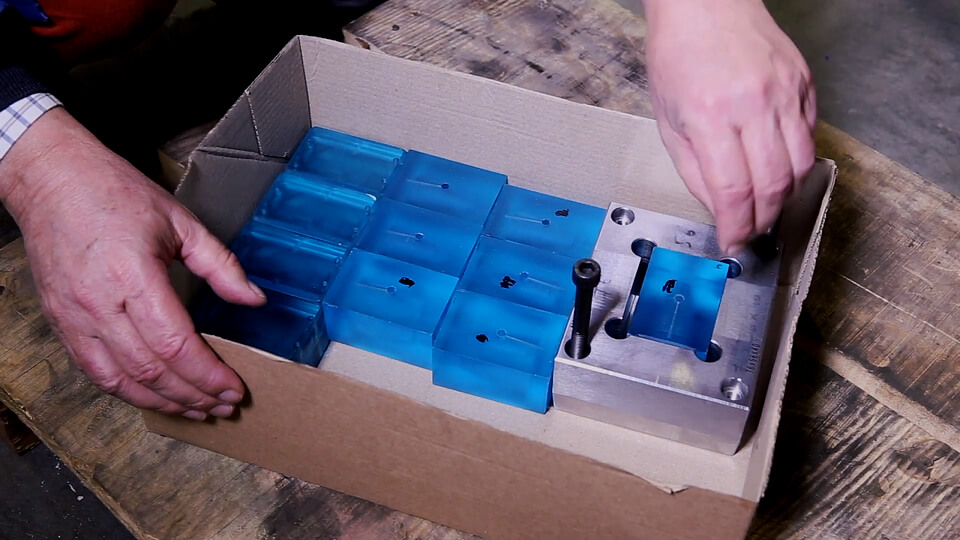

But thanks to the MCAM SPRINT (Soluble Printed Injection Tooling) system, engineers can now 3D print their molds in a soluble resin, and use them as they would a traditional metal mold. When the plastic has been injected into the mold and has cooled, the mold can be released from the injection molding system and washed away leaving the fully formed injection molded part intact.

The result is a strong, stiff, lightweight fully dense part, that is free from the design limitations of traditional injection molded part design (such as draft angle inclusion).

Of course, being soluble, it means this is a one-shot only process, so this SPRINT process is aimed largely at those wishing to create prototypes before committing to a full metal mold design (and cost). It is also suitable for small production runs, depending on individual scenarios. The KyronMAX plastics are transferable to full production injection molding systems, so users such as Delson Aeronautics can rest assured that the materials they use for prototyping can also be used for production – no need to consider revised material properties when scaling up.

In terms of the plastics available for use in the SPRINT system they come in a range of flavours including filled Nylons and PEEKs offering a range of strengths and stiffnesses.

Quiet Propellers

So that is how Delson Aeronautics are using AM for rapid prototyping of injection molded engineering plastic parts. Let’s have a look at the winning propellers in action.

The video below shows a comparison of some commercially available (and noisy) propellers versus the Delson propellers. Turn the volume up to hear the difference!

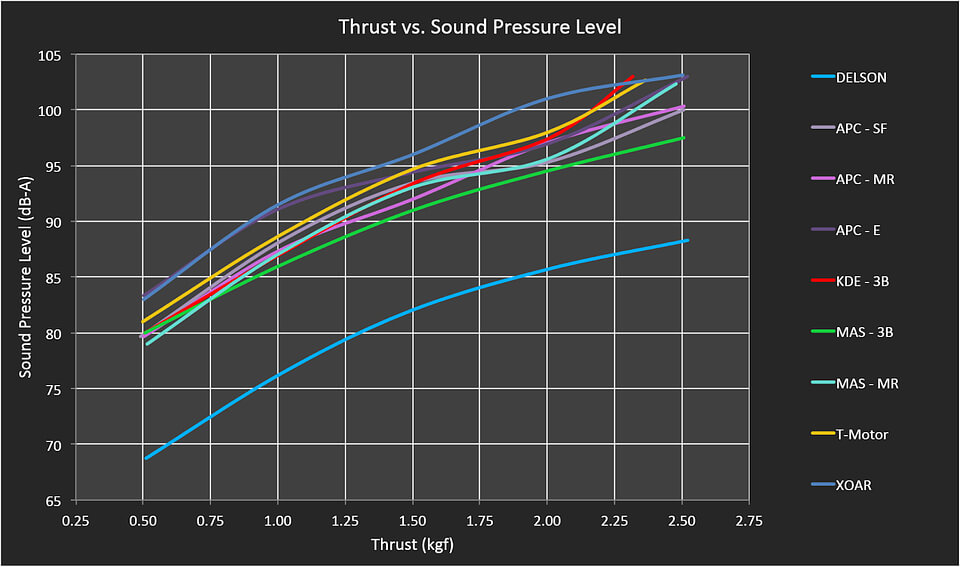

Pretty quiet, right? That reduction in noise is equal to a 50% reduction in sound pressure, as you can see in the graph below.

The team at Delson Aeronautics will work with the MCAM team over the coming months to develop their product, and the new super quiet propellers should hit the market sometime later in 2021.

If you would like to know more about SPRINT or get a quote or discuss some work, then you can upload your file over at this link.

And if you would like to follow Delson Aeronautics on their path to production, you can check out their development log over here.