Swedish nuclear power plants are implementing 3D printing to address spare parts challenges as reactors extend their operating lives to 80 years. According to Björn Forssgren, metallic materials specialist at Ringhals nuclear power plant, the ability to control production internally could “contribute to increased availability for our production units, meaning more fossil-free electricity production.”

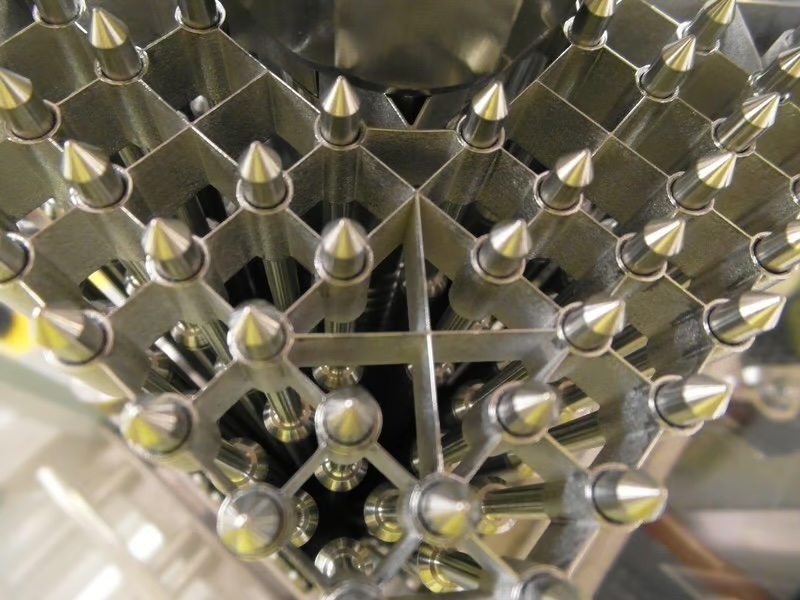

In 2017, Ringhals joined a collaborative 3D printing initiative with other companies, now managed by Research Institutes of Sweden (RISE). The partnership, which has expanded to 21 companies, focuses on developing AM capabilities for various components including pipes, valves, and pump housings. Testing shows that 3D-printed parts maintain equivalent or superior structural integrity compared to traditionally manufactured components.

AM-manufactured parts are already installed in all three Swedish nuclear power plants: Ringhals, Forsmark, and Oskarshamn. Current applications are limited to components not exposed to high pressure, though international standards for pressure-exposed parts are in development. “We hope that such a standard will be ready in the near future. Once it is ready, we can really start looking at installing components in our plants,” says Forssgren.

The technology offers several advantages over traditional manufacturing methods. These include minimal material waste, faster production times, and the ability to digitally store designs rather than physical inventory. A modern 3D printer with four laser sources can produce up to 170 cubic centimeters of material hourly, making it an efficient production method.

Vattenfall, which owns five of Sweden’s six nuclear reactors, is exploring the possibility of establishing an in-house 3D printing facility. Such a facility could potentially supply parts to other nuclear plants and power generation facilities within the company. “The plants are not getting any younger, and AM is a tool for achieving our availability targets and reducing the risk of production disruptions,” Forssgren explains.

Source: group.vattenfall.com