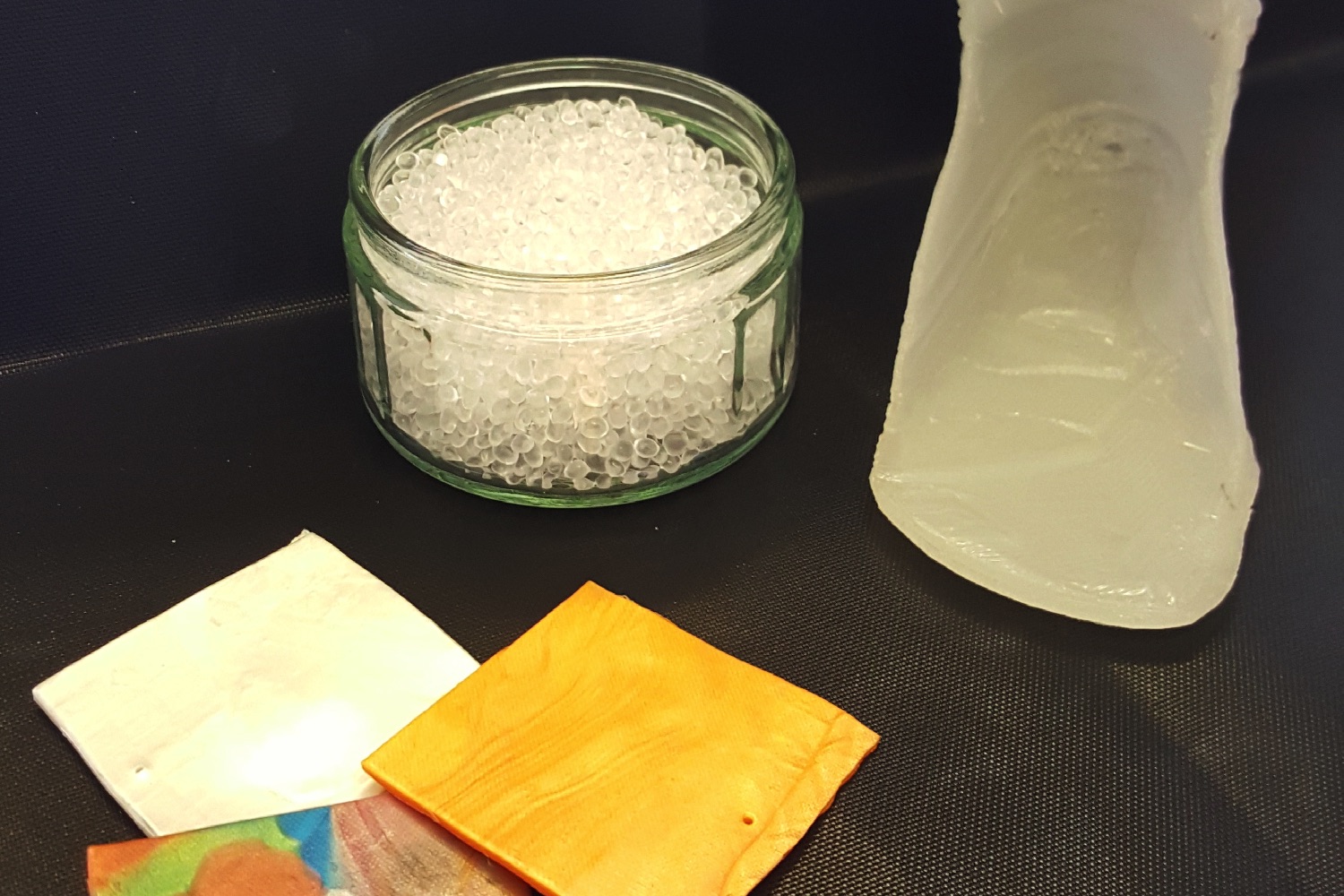

Torc2 has developed a new material that is reusable because it can melt at low temperatures. The company is looking at the material as a safe and easy way to produce plastic prosthetics. While Torc2 primarily works on medical innovations, this material could have other diverse uses as well.

The material itself is a blend of polymers. The thermoplastic shifts to a putty-like state at a staggeringly low temperature of 55 °C (131 °F). At body temperatures, the material reaches a rigid, rubberized plastic-like state. This property makes it very unique and allows for very interesting options in terms of practical applications.

Torc2 Applications

“What we’ve developed is a blend of polymers with a low melting point,” CEO Gary Blundell. “What we’re hoping to do is to replace Plaster of Paris casts with a material that can be remolded at a temperature that’s comfortable for human contact. This means that any adjustments which need to be made can be done so while the patient is wearing it.”

This allows for doctors to mold the prosthetics into the precise shape on the affected area without harming the patient. As a result, this can create far more accurate casts that fit the patient precisely. The company’s CEO has also stated that they have does extensive tests for durability and the material has passed with flying colours. Aside from durability, doctors can reuse the cast materials to simply adjust the cast as opposed to creating a new one. This cuts down on material costs immensely.

Outside of the medical field, another possible application of this material is in education. Educational 3D printing generally requires low temperature machines and easy to use materials. With its reusability and low melting point, this material could be safe and efficient for practice.

Admittedly, there are some applications that are out of the question precisely because it has such a low melting point. For example, it won’t be useful for heavy industrial applications in heavy heat areas. The company is still working on getting it through the preliminary clinical trials. The material may not be on the market any time soon, because tests such as this can be very extensive. However, it is still a promising new material that many an industry could make great use of.