TU Graz researchers have perfected the 3D printing of optically active nanostructures, enabling precise simulation and production. Over the past decade, the team, led by Harald Plank, Verena Reisecker, and David Kuhness, have achieved breakthroughs in simulating and fabricating complex, free-standing 3D architectures with individual features smaller than 10 nanometres.

The traditional trial-and-error method for creating three-dimensional nanostructures, which involved painstaking efforts to achieve desired optical properties, is now obsolete. The team’s innovation allows the accurate simulation of nanostructure shapes and sizes in advance, aligning with the desired optical properties, eliminating the need for a time-consuming trial-and-error process.

A key achievement is the removal of chemical impurities incorporated during the initial production without compromising the integrity of the nanoarchitectures. This breakthrough not only ensures precision in production but also opens avenues for new optical effects and application concepts due to the three-dimensional aspect.

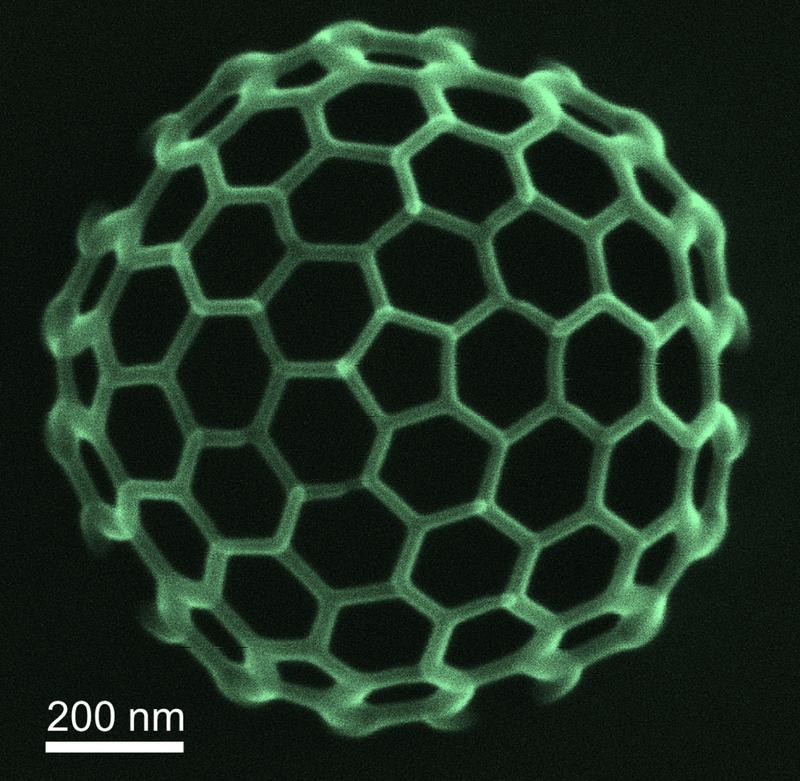

The technology developed by TU Graz is currently unparalleled globally, allowing the production of intricate 3D structures on nearly any surface with individual features smaller than 10 nanometres. The researchers employ focused electron beam induced deposition, exposing surfaces to special gasses under vacuum conditions. The finely focused electron beam precisely controls the deposition process, enabling the creation of complex nanostructures with lattice- or sheet-like building blocks in a single, controlled step.

This development not only eliminates the tedious trial-and-error approach but also provides unmatched precision in creating three-dimensional nanostructures. The future holds exciting prospects for optical effects and applications in various fields, propelled by TU Graz’s advancements in 3D printing at the nanoscale.

You can read the full research paper, titled “Spectral Tuning of Plasmonic Activity in 3D Nanostructures via High-Precision Nano-Printing” at this link.

Come and let us know your thoughts on our Facebook, X, and LinkedIn pages, and don’t forget to sign up for our weekly additive manufacturing newsletter to get all the latest stories delivered right to your inbox.