Penn State researchers have developed a new multi-material 3D printing technique that successfully fuses two different metals into a single complex structure. The team used a process called multi-material laser powder bed fusion to print a structure combining low-carbon stainless steel and bronze. This achievement was made possible through Penn State’s Center for Innovative Materials Processing Through Direct Digital Deposition (CIMP-3D), which acquired an Aerosint selective powder deposition system in August 2023.

“In a process called selective powder deposition, we can now melt multiple powdered metals in a single layer during the additive manufacturing process — and we were the first university in the U.S. to do so,” said Jacklyn Griffis, doctoral candidate in mechanical engineering and first author of the paper published in npj Advanced Manufacturing.

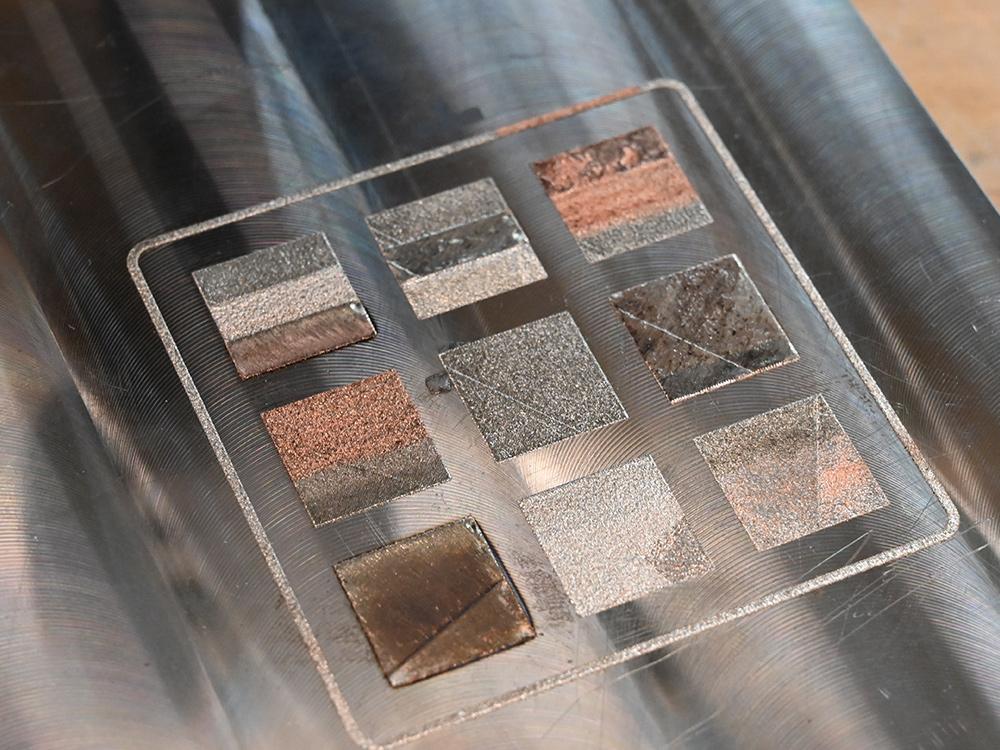

The researchers focused on analyzing how build orientation affected the quality of the final product. They created a complex shape known as a gyroid, which has applications in heat exchangers and biomedical implants. The team examined defects such as cracking and porosity, interfacial microstructures, and element diffusion across the interface to understand how these factors impacted performance.

“Penn State has always been a leader in metal additive manufacturing, but we now have the ability to manufacture complex multi-material parts, where we can not only make complex designs but control precisely where each material is placed,” explained Guha Manogharan, associate professor of mechanical engineering and co-director of CIMP-3D.

The research team utilizes CT scans to produce digital 3D renderings of parts, allowing them to identify potential issues like pores and micron-scale defects. This capability enables real-time monitoring of the manufacturing process. According to Griffis, a one-centimeter-tall metal part includes thousands of layers of metal powder and takes several hours to print.

Future work will focus on transforming this 3D printing method into a more robust, production-ready process through in-process monitoring. The team also plans to incorporate additional metal alloys such as Inconel and copper. The research was supported by the Applied Research Laboratory’s Walker Graduate Assistantship and the U.S. National Science Foundation.

Source: psu.edu