FDM is a popular choice when it comes to YouTubers and hobbyists 3D printing drones, but the extrusion technology does have its limitations. One engineer based in the United Arab Emirates has turned to photopolymer resins (and other technologies) to overcome the limitations found in the FDM process.

Nomad Prototypes was founded by aerospace engineer and additive manufacturing expert Phillip Keane to develop drones using additive manufacturing and topology optimisation. Their plan is to build the world’s largest 3D printed drone using a variety of additive manufacturing methods.

“Filament extrusion is fine for small multirotors, and small hobby-grade fixed wing aircraft, but really runs into issues when scaling up in size for professional-grade fixed wing drones,” said Keane.

“FDM results in anisotropic prints, and the complex dynamic forces acting on fixed wing aircraft, regular extrusion just doesn’t cut it in terms of strength and weight. The whole point of 3D printing drones is to minimize weight, but when there is a tendency to add more layers to the structure walls to compensate for the anisotropy, you quickly reach a point where you’re better off just using fiberglass or carbon fiber.”

Traditional methods such as fiber glass, while capable of producing strong and lightweight drones, are labor-intensive and costly due to the sheer amount of manual labor involved. And due to the hands-on nature of composite manufacturing, quality issues can arise due to variations in the process. By utilizing 3D printing, Nomad Prototypes aims to reduce labor costs, while maintaining quality, strength, and reducing weight.

The company’s founder has investigated a number of drone printing methods, including FDM, SLA, SLS, MJF, and FGF, over the last decade.

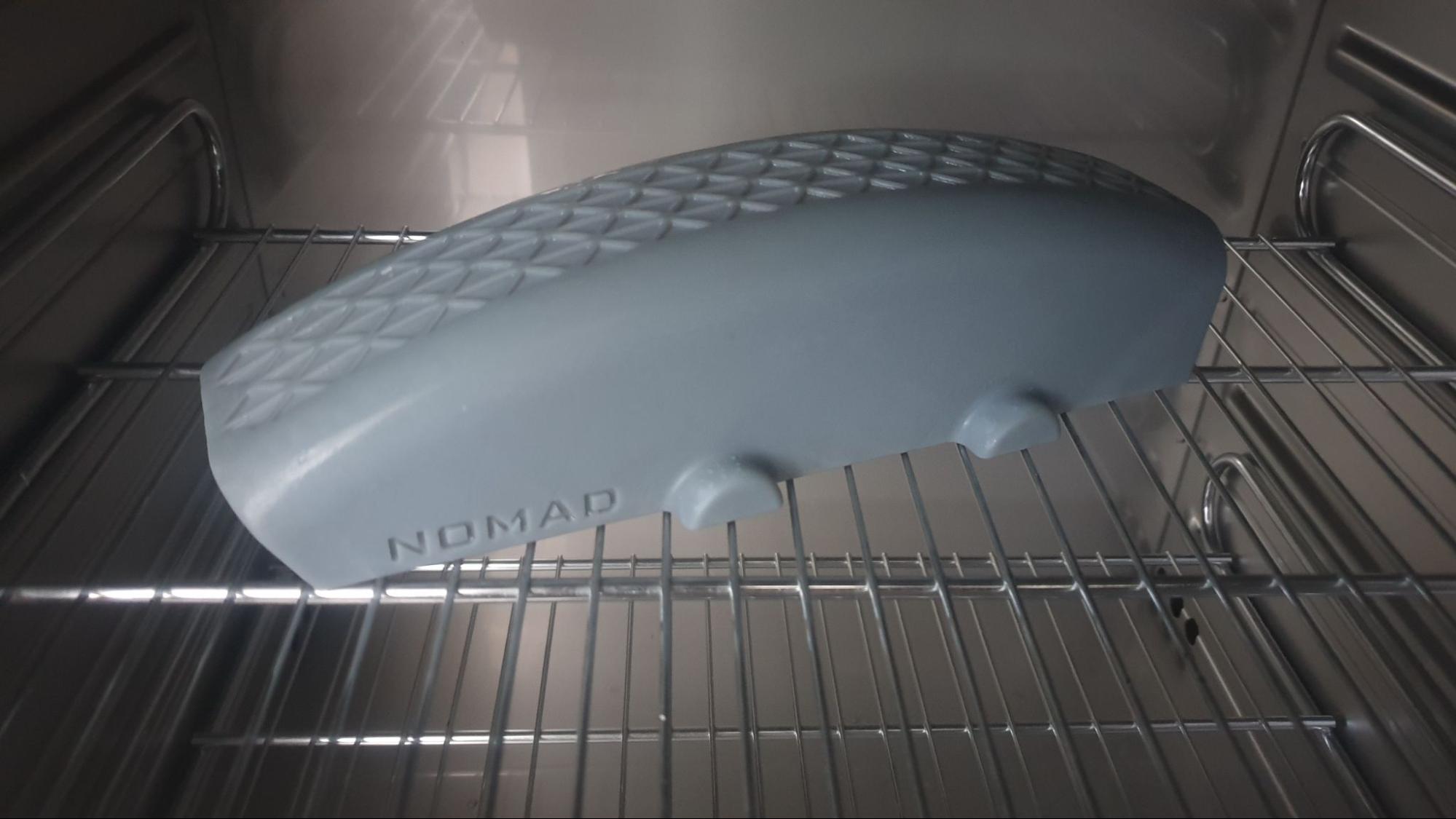

The first generation of drones from Nomad Prototypes are multirotors, made with Liqcreate StrongX resin, which is one of the strongest photopolymer resins available. Liqcreate is a dual-cure resin, meaning it is first cured with UV, and then given a final thermal cure to further increase the strength.

To enhance the printed part, it is sandblasted and a ceramic coating is applied to increase durability, and UV-resistance.

“With the Liqcreate resin and nTop software, we have been able to create wall thicknesses measuring just 500 microns thick,” said Keane.

“Without the lattices holding the skin together, the thin walls would usually just collapse during the resin printing process. But the lattice serves as a scaffold during printing, which means we can print skin elements much thinner than even Liqcreate thought possible.”

The combination of lightweight structure, 7000 mAH battery and efficiently sized motors/props allows the 1st generation drone to stay airborne for 37 minutes (without payload), and 22 minutes with a 500 gram payload.

The second generation will be a small-scale modular multirotor, which can convert to a fixed wing / VTOL configuration, and will also be printed with a strong and flexible resin, and will utilize topology optimization in the wing sections, creating extremely thin and durable wing skins – a feat unattainable with FDM.

The third generation drone will scale up to a 3.2 meter wing, and will be 3D printed with high strength pellets.

“Some of these new pellets have incredibly high carbon fiber loads, reaching up to 50% carbon fiber. This would be impossible to print in filament format, as the filament is so stiff, it would snap as soon as it reaches the extruder,” said Keane.

“These pellets can print parts that are over 3x the strength of regular FDM filaments, so the problems caused by anisotropy are reduced. We can effectively print thinner parts, and still maintain a high degree of strength in the structure, which makes pellets viable for fixed wing drones.”

As for the resins drones, development will continue on those, in order to iron out the creases in the design, until the geometry is ready to scale up for the pellet printed version.

“High quality resins are accessible, and can be printed on a $3,000 machine, unlike SLS powders which need much more expensive machines to print with,” said Keane.

“Printing the smaller scale drones with the resins allows us to refine the design in terms of DFM and DFA before switching to another process.”

The company also has a custom sizing algorithm that uses MATLAB to generate the correct geometry for fixed wing aircraft. They plan to use the second generation fixed-wing resin drone to verify and validate the algorithm before scaling up to their 3.2 meter wingspan version.

“Multirotors are super-easy to design and don’t require too much thought,” said Keane.

“But designing fixed wing aircraft from scratch is vastly more complicated, especially when using new materials and topology optimization. This is why we are taking a careful and iterative approach with our drones, with each subsequent drone building on the lessons of the previous generation.”

Nomad Prototypes will be presenting their project at the Make It In The Emirates pitch contest in Abu Dhabi Energy Center on Monday 27th May.